- Home

- Companies

- Henan Greatwall Machinery Co., Ltd.

- Products

- Greatwall - Sand Washing and Fine Sand ...

Greatwall - Sand Washing and Fine Sand Recycling Machine

The sand washing &fine sand recycling machine is used in the wet sand production line. It combines the advantages of a sand washing machine and a de-watering screen, which give consideration to both functions of sand washing and sand and stone material dehydration.

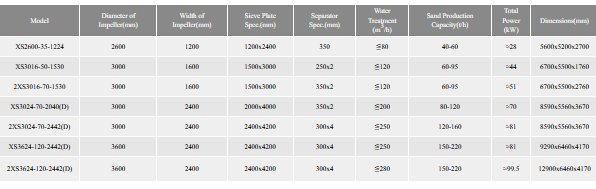

- Processing Capacity: 40-220T/H

- Max. Feeding Size:<5mm

- Application Fields: It is used in the wet sand production line.

- Applied Materials: Widely used in various ores, such as granite, marble, limestone, feldspar, swallow stone, etc.

- Customized Service:Small, medium and large models can be customized to meet your needs.

The sand washing & fine sand recycling machine is used in the wet sand production line. It combines the advantages of a sand washing machine and a sand de-watering screen, which give consideration to both functions of sand washing and sand and stone material dehydration. It can make the produced sand meet the nation`s standards and completely solve the problems of excessive water content, excessive humidity, large mud content, more dust, and more impurities in the sand .it is a new type of environmental protection sand washing equipment.

This machine mainly plays the role of water and sand separation, and the commonly used materials are kaolin, mud, sand and gravel aggregate, artificial sand, coarse coal slime, concrete mixing station, and other fine materials recycling and reusing. It’s widely used in construction, transportation, sand and gravel plants, water conservancies, and other fields.

- Low energy consumption, convenient installation and transportation of the whole machine, and low failure rate.

- Easy to operate, a polyurethane sieve plate is not easy to block and has a long service life.

- The recovery of ultrafine particles below 0.2mm is more than 95%.

- Low investment and high return.

- Indispensable important link between wet sand making and sand washing.

- The mud, water, dust, and impurities in the sand are greatly reduced and the quality and price of sand are improved.

Structure composition: it is composed of a dehydration screen, wheel bucket, cleaning box, reducer, motor, vibration motor, and other parts.

Working principle: the sand water mixture enters into the washing box of the sand washing machine, is filtered and screened by the wheel bucket screen, and falls into the dehydration screen for dehydration treatment. The sand was removed from the excessive moisture in the sand and can wash away a large amount of soil and stone powder left in the original sand.