Wilden - Sanitary/Hygienic Air Operated Diaphragm Pump

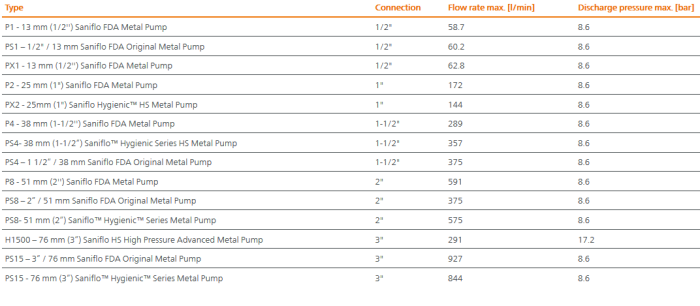

Wilden is a worldwide leader in hygienic and biopharmaceutical air-operated double-diaphragm pumps and provides a wide spectrum of solutions for various applications in the food, beverage, dairy, body care and biopharmaceutical industries. Wilden`s Saniflo FDA and Hygienic HS AODD pumps were developed to meet the highest standards and requirements in the industry.

Wilden`s sanitary/hygienic and biopharmaceutical AODD pumps have the versatility, security and capacity to pump a variety of viscosities, solids and shear-sensitive products efficiently.

These pumps are provided with stainless steel components and are available in a variety of sizes and with different surface finishes. All Saniflo pumps have clamp connectors for easy cleaning in the right place (CIP). Three air distribution systems (ADS) are available for Saniflo pumps, including the revolutionary, patent-pending Pro-Flo™ SHIFT, featuring 60% less air consumption, more yield per SCFM, precisely metered air consumption for reduced product waste and MTBR.

As a globally leading provider of air-operated double-diaphragm (AODD) pump technology, Wilden is on hand to support your industry. Wilden is aware that safety, security, performance, hygienic requirements and careful transport of your products are determining factors in your choice of process equipment.

Conformity

Saniflo Hygienic HS pump confirmity

- EHEDG

- 3-A

- FDA CFR 21.177

- USP Class VI

- 1935/2004/EC

- ATEX

- CE

Saniflo FDA pump confirmity

- FDA CFR 21.177

- USP Class VI

- 1935/2004/EC

- USP Class VI

- ATEX

- CE

- Higher flow rates and increased pump output

- Multiple hygienic/sanitary elastomers available

- Clamp connectors for faster maintenance and CIP cleaning

- Variable flow and pressure

- Suitable for shear-sensitive fluids

- Self-priming

- Dry-run safe

- Transportable and submersible

- Solid material passage

- Offset valve housing for easy alignment

- Simple operation and maintenance

- Maximum mean time between repairs (MTBR)

- No dry-run damage

- Lubrication-free operation

- Increased on/off reliability

- Higher flow rate per SCFM inlet

- Reduced air and kilowatt consumption

- Lower operating costs and less downtime