- Home

- Companies

- Sentry Air Systems, Inc.

- Products

- SAS - Ductless Fume Hoods

SAS - Ductless Fume Hoods

Ductless Fume Hoods, also known as Ductless Containment Hoods or Fume Hoods, are self-contained workstations that help to protect the operator's breathing zone from harmful airborne fumes and particulate. These containment systems are used for a variety of applications, including chemical fume control, powder & dust removal, solvent vapor control, pharmaceutical powder filling, light grinding, acid gas fumes, anesthesia gas containment, epoxy fume control, and many more applications that produce particulate and fume.

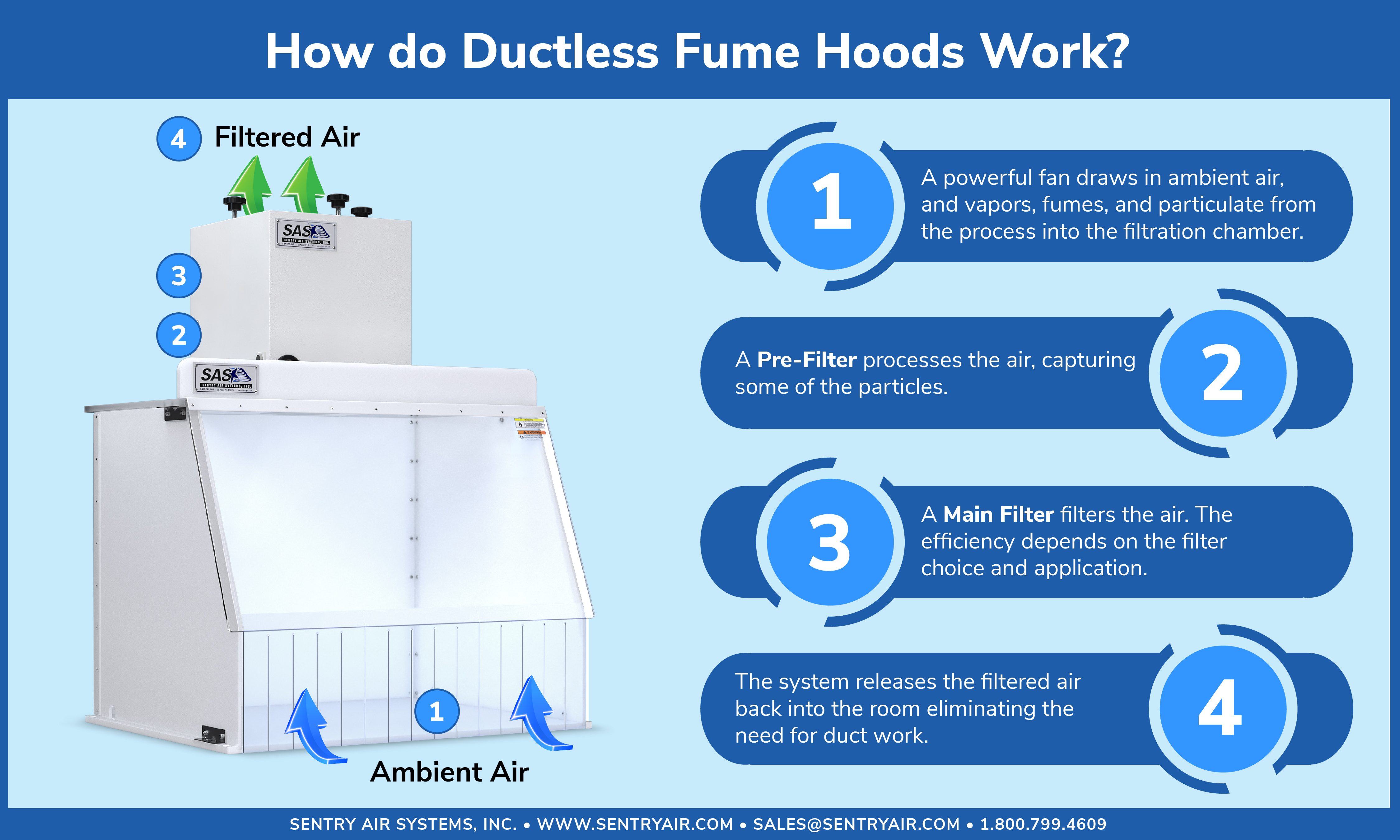

Ductless Fume Hoods are equipped with a powerful fan that pulls the air in through the hood's inlet and into the filtration system. This system is designed to keep harmful airborne contaminants away from the operator's respiratory zone while they work within the hood. Various filter media is used depending on the chemical vapors/and or particulate that are generated (such as HEPA and ULPA filters, Activated Carbon, or specialty-blended media like ammonia, mercury, acid gas, and aldehyde). Because the air is recirculated, no exterior-ducting or make-up air is necessary when using a ductless fume hood.

Ductless Fume Hoods, manufactured by Sentry Air Systems, offer a portable, easy-to-maintain solution that protects your lab personnel from harmful types of carbon, airborne fumes and chemicals. Typically used in locations where outside ventilation isn’t possible or will be costly to install, the ductless fume hood produces a recirculating air pattern filtered through high efficiency air filters and requires no external ducting or venting.

A ductless fume hood is a stand alone, compact workstation that provides a continuous flow of air that filters hazardous fume vapors out, recirculating clean air back into your working environment. Because the air is recirculated, no exterior ducting or makeup air is necessary. These air filtration systems are designed to keep harmful airborne contaminants away from the operator`s respiratory zone while they work within the hood.

Also referred to as exhaust hoods, these containment systems are used for a variety of applications including chemical fume control, powder and dust removal, solvent vapor control, pharmaceutical powder filling, light grinding, acid gas fumes, anesthesia gas containment, epoxy fume control and other applications that produce hazardous particulates and fumes.

Ductless fume hoods offer several key advantages when weighing your options versus a ducted fume hood:

- No costly ducting or venting

- No permitting issues for venting outside of the building (ie. EPA air sampling)

- Adaptable (mobility and ease in change of layout)

- Environmentally friendly

- Significant energy cost savings

However, a ductless fume hood may not be suitable for the application being practiced as there are certain features of a ducted hood that may suit your needs more:

- Certain chemicals/gases carry a low molecular weight and are not efficiently captured through a carbon filter (ie. methane, butane, propane gas)

- Loading: the amount of uses per time frame may require us to directly vent outside versus running through a particular filter “too much”

- For example: If your application is using acetone gas and evaporating gallons per day, running it through a carbon filter in excess may saturate it past an effective point, rendering it to be useless or replaced at a significant rate.

- Dangerous chemicals that need to be vented outside per regulations of OSHA. NIOSH

- Minimal installation costs—no external ducting or venting

- Portable

- Minimal maintenance

- Environmentally friendly

- Significant energy cost savings

- No permitting issues for venting outside (ie. EPA air sampling)

- UL-certified: Our line of Deluxe Ductless Fume Hoods is UL-certified. UL-certified products have been third-party verified for electrical and operator safety. File number: E466130 for US and Canada.

Safe operation of your fume hood is critical to protecting your staff and anyone around it. A ductless fume hood should only be considered for use in labs with low hazard chemicals.

- They should be visually inspected frequently

- Pedestrian traffic in front of the hood should be limited

- Any bulky equipment should be placed at the rear of the hood

- To allow for airflow, large equipment should be raised at least 2” off the surface

- If your fume hood is used often, a regular cleaning schedule should be established

Sentry Air invests in certification processes and independent testing performed by a Nationally Recognized Testing Laboratory (NRTL) prior to offering any air infiltration products.

Hood Dimensions:

- O.D.: 24"D x 32"W x 25"H

- I.D.: 23.5"D x 30"W x 24"H

Hood Material:

- Sides: .250" White Acrylic

- Base: .500" White High Density Polyethylene

- Top: .500" Clear Polycarbonate

Front Windows:

0.250" Clear Polycarbonate

Motor:

Fractional Horsepower

Total Weight:

Approx. 100 lbs.

Available Filter Efficiencies:

HEPA Filter - Up to 99.97% efficient on particles down to 0.3 microns

ASHRAE Filter - Up to 95% efficient on particles down to 0.5 microns

ULPA Filter - Up to 99.9995% efficient on particles down to 0.12 microns

Activated Carbon & Specialty-Blended Filters - Efficiency varies per chemical.

Blower Dimensions:

13" L x 13" W x 14.5" H

Approximate Inlet Velocities:

Pre-filter & 99.97% HEPA Filter - 100 FPM

Pre-filter & Heavy-duty Carbon Filter - 60 FPM

Electrical:

115/1/60, 2 amps

Sound Level:

61 to 66 dba (Blower Speed: Low to High)

Max Operating Temperature:

Not to exceed 170 degrees Fahrenheit

Warranty:

Limited two-year warranty from date of shipment on defects due to materials or workmanship.

Patented Design:

U.S. PATENT #5,843,197

Environmentally-Friendly: In many cases, ducted exhaust hoods empty extracted fume and particulate directly outdoors without sending it through a filtration system first. Ductless Fume Hoods trap hazardous particulate in filters so they can be disposed of properly.

Energy Efficiency/Cost Efficiency: Ductless Fume Hoods recirculate existing room air, while externally ducting systems remove heated, cooled, or dehumidified air outdoors, which requires that air to be replaced. This has the potential to waste energy and increase cost.

Minimal Maintenance & Installation Requirements/Easy Mobility: While externally ducting exhaust hoods require complicated installation because of ducting construction, Ductless Fume Hoods can be up and running with minimal installation. They are essentially “plug and play” solutions. Ductless Containment Hoods do not require any ducting or external venting and can be moved from location to location with relative ease. The only maintenance requirements are replacing saturated filters and wiping the hood down with appropriate cleaning supplies from time to time.