- Home

- Companies

- SBM Ultrafine Powder Technology Co., ...

- Products

- SBM - Hammer Crusher Stone Breaker

SBM - Hammer Crusher Stone Breaker

The hammer crusher stone breaker is a one-stage crusher that directly crushes materials with a maximum particle size of 600-1800 mm to 25 or below 25 mm. Hammer crusher stone breaker is a kind of industrial machinery, the principle is to crush the material by the collision of the high-speed rotating hammer body and the material. It is suitable for mining, cement, coal, metallurgy, building materials, highway, combustion, and other departments to finely crush medium-hard and brittle materials.

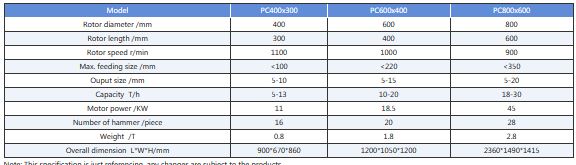

- Output Size: 5-20 mm

- Feed size.:

- Capacity: 5-30 t/h

Applicable materials: The hammer crusher is suitable for crushing medium-hard materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgy and other industrial sectors.

Product features: PC hammer crusher is a kind of industrial machinery, the principle is to crush the material by the collision of the high-speed rotating hammer body and the material.

Hammer crusher Application fieldsHammer crusher stone breaker is used for various ores with compressive strength not exceeding 100MPa and moisture content less than 15%.

The hammer crusher stone breaker is used to crush various medium-hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. Such as coal, salt, chalk, gypsum, bricks, limestone, shale, etc.

It can also be used to crush wood, paper, or crushed asbestos cement with a strong fiber structure, elasticity, and toughness to recycle asbestos fibers.

In addition, the hammer crusher stone breaker can not only be used in crushing production lines, sand production lines, but also in the beneficiation production line instead of cone crushers.

Hammer crusher Crushing materialsThe hammer crusher stone breaker is suitable for crushing medium-hard materials such as coal, limestone, gypsum, slag, coke, coal, soft refractory materials and other materials in cement, chemical, electric power, metallurgy and other industrial sectors.

STRUCTURE OF hammer crusher stone breaker:Hammer crusher stone breaker is mainly composed of frame, rotor, supporting iron, and grate.

The frame is divided into upper and lower parts, which are welded after cutting steel plates. The frame lining is made of high manganese steel, which can be replaced after wear.

The rotor is composed of the main shaft, a turntable, a pin, and a hammer, and the turntable, a pin, and a hammer are regularly combined in the main shaft. The motor drives the rotor to rotate rapidly in the crushing cavity, and the hammer spreads outward under the centrifugal force of the rotor rotation.

WORKING PRINCIPLE OF hammer crusher stone breaker:

The bulk material entering the crusher through the feed port is hammered, impacted, cut, and ground into small sizes at high speed.

After crushing, the qualified materials are screened out from the gap of the grate, and the unqualified materials are left in the crushing cavity for further hammering and grinding until they reach the standard particle size.

The size of the final product can be adjusted by replacing the furnace bar. The gap between the rotor and the grate can also be adjusted according to different requirements.

Simple structure

The overall design has the advantages of beautiful appearance, compact structure, few wearing parts and convenient maintenance. It is an upgraded product.

It has the characteristics of a simple structure, a large crushing ratio, and high production efficiency. It can be crushed in dry and wet forms.

Strong applicability

The crushing ratio is large, the production efficiency is high, and the applicability is strong. The required particle size can be adjusted according to customer requirements.

Efficient and environmentally friendly

There is no screen mesh bottom, no requirements for the moisture content of the material, there is no problem of clogging the sieve plate, and there is no problem that the material cannot be discharged in time and repeated crushing; the structure of the hammer breaks the machine body to be sealed, which solves the dust pollution in the crushing workshop. And the problem of body dust leakage.

Advanced technology

The bearing box is all made of steel castings and fixed with four screws, which is scientific and practical; the working hammer is cast with a new process, which is wear-resistant and impact-resistant.

Durable

The working hammer is cast with a new technology, which is wear-resistant and impact-resistant.

Flexible

The required granularity can be adjusted according to customer requirements.

Clean

The structure of the machine body is sealed, which solves the problems of dust pollution and ash leakage of the machine body in the crushing workshop.

Reasonable structure

The overall design has the advantages of beautiful appearance, compact structure, few wearing parts, and convenient maintenance. It is an upgraded product.