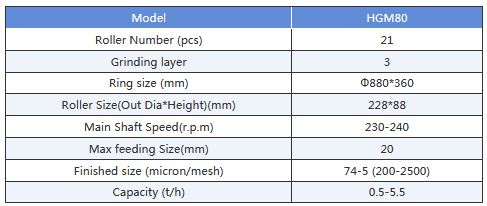

SBM - Model HGM80 -Micro Powder Grinding Mill

HGM Micro Powder Grinding Mill has been proved a new type of mill with outstanding features and stable quality by thousands of customers. It was designed by our engineer and technicians on the basis of multiple innovation, test and experience, and absorbed many advantages of manufacturing technique of mills domestic and aboard. It is the ideal equipment for production of micro powder in the fields of mining, chemical industry, metallurgy and construction etc.

Maxing Feeding Size: 20 mm

Ouput Size: 74-5 micron (200-2500 mesh)

Capacity: 0.5-5.5 t/h

Applicable materials: calcium carbonate, limestone, gypsum, kaolin, bentonite, calcite, dolomite, talc, mica, barite

Product features: High Efficiency| Long life cycle of spare parts| High safety and reliability| High fineness, flexible adjustment| Environment-friendly| Advanced intelligent speed control device.

HGM Series Micro Powder Grinding Mill is suitable for grinding and processing of modest and soft non-inflammable and non-explosive brittle materials, such as calcium carbonate, limestone, gypsum, kaolin, bentonite, calcite, dolomite, talc, mica, attapulgite, barite and graphite. So far, it has been widely applied in paint, coating, paper-making, pigment,rubber, plastic, padding, cable, cosmetic, chemical supplies and many other industrial fields.

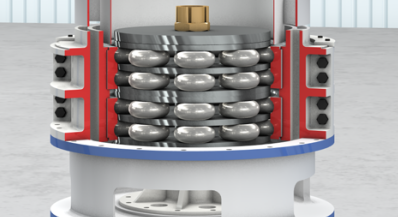

HGM series micro powder grinding mill mainly consist of main unit, classifier, powder collector(all models removed out except HGM80), bag filter, draft fan, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and belt feeder. After crushed by crusher, the large materials become small ones and are sent to storage hopper by bucket elevator, and then evenly sent to the upper distribution plate of the turn plate by belt feeder and sloping feeding pipe. When the grinding mill is working, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turn plate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grind by the rollers.

The high-pressure air fan constantly inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the bag filter, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

More mature grinding curve, higher production capacity, and lower energy consumption

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency. With the same finish fineness and power, the production capacity is 40% higher than that of jet mill and stirred mill, and the yield is twice as large as that of ball mill. However, the system energy consumption is only 30% of the jet mill.

More mature grinding curve, higher production capacity, and lower energy consumption

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency. With the same finish fineness and power, the production capacity is 40% higher than that of jet mill and stirred mill, and the yield is twice as large as that of ball mill. However, the system energy consumption is only 30% of the jet mill.

The core part using rolling bearing without screw, the equipment operation is safer

The grinding chamber has no rolling bearing and screw inside, so that there is no damage problem of bearing or its sealing parts, and there is no machine damage problem caused by loose screw. The lubricating device is installed outside of the main shaft, so that lubrication without shutdown can be realized externally, and the production can be continued for 24h/d.

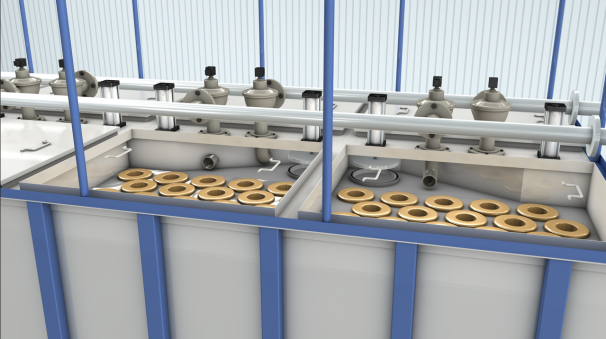

Pulse off line type bag filter, high level of environmental protection

High-efficiency pulse dust collector is adopted, and no dust pollution will generate during the operating process of the entire equipment; silencer and noise elimination room are configured to reduce the environmental noise, and the production is organized fully according to the national environmental protection standards. The use of silencer can effectively reduce the dust pollution and noise, meet the national environmental protection standards, and cause no pollution to the surrounding environment.

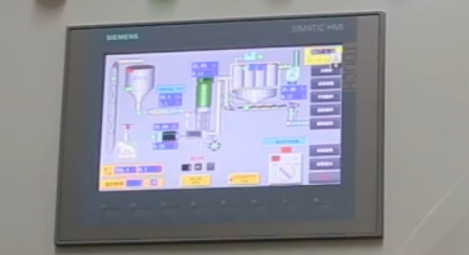

PLC Control System

The PLC control can make sure one key start and one key stop, which avoid improper operation to cause damage to the machine.Also, the operation will be done through touching Siemens KTP screen ,which also can connect with PC, this make sure real-time production monitoring.

Variable-frequency drive(VFD) using for main unit, blower , classifier and feeder .

The VFD for main unit, it can change mill running speed , when material is hard for grinding, such as talc,graphite, then it can reach superfine size , also it can save much power, the VFD cost can get back by saving power within 8 months.

The VFD for blower will make sure running speed of blower adjustable, when customer making different mesh size powder,the blower air capacity also need be adjusted.

The VFD will be added for classifier and feeder in every configuration,because this two part must be VFD controlled. In a word, VFD can make machine working smoothly and can save much more power.

More mature grinding curve, higher production capacity, and lower energy consumption

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency. With the same finish fineness and power, the production capacity is 40% higher than that of jet mill and stirred mill, and the yield is twice as large as that of ball mill. However, the system energy consumption is only 30% of the jet mill.

More mature grinding curve, higher production capacity, and lower energy consumption

Newly designed grinding curves of grinding roller and grinding ring further enhance the grinding efficiency. With the same finish fineness and power, the production capacity is 40% higher than that of jet mill and stirred mill, and the yield is twice as large as that of ball mill. However, the system energy consumption is only 30% of the jet mill.

The core part using rolling bearing without screw, the equipment operation is safer

The grinding chamber has no rolling bearing and screw inside, so that there is no damage problem of bearing or its sealing parts, and there is no machine damage problem caused by loose screw. The lubricating device is installed outside of the main shaft, so that lubrication without shutdown can be realized externally, and the production can be continued for 24h/d.

4. Pulse off line type bag filter, high level of environmental protection

High-efficiency pulse dust collector is adopted, and no dust pollution will generate during the operating process of the entire equipment; silencer and noise elimination room are configured to reduce the environmental noise, and the production is organized fully according to the national environmental protection standards. The use of silencer can effectively reduce the dust pollution and noise, meet the national environmental protection standards, and cause no pollution to the surrounding environment.

5. PLC Control System

The PLC control can make sure one key start and one key stop, which avoid improper operation to cause damage to the machine.Also, the operation will be done through touching Siemens KTP screen ,which also can connect with PC, this make sure real-time production monitoring.

6. Variable-frequency drive(VFD) using for main unit, blower , classifier and feeder .

The VFD for main unit, it can change mill running speed , when material is hard for grinding, such as talc,graphite, then it can reach superfine size , also it can save much power, the VFD cost can get back by saving power within 8 months.

The VFD for blower will make sure running speed of blower adjustable, when customer making different mesh size powder,the blower air capacity also need be adjusted.

The VFD will be added for classifier and feeder in every configuration,because this two part must be VFD controlled. In a word, VFD can make machine working smoothly and can save much more power.