ScaleBuster - Water Conditioner Technology

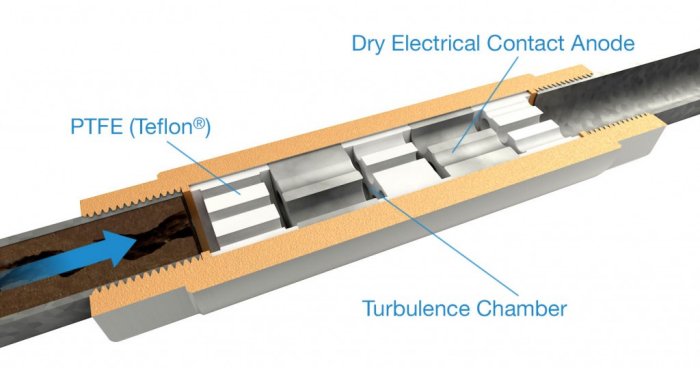

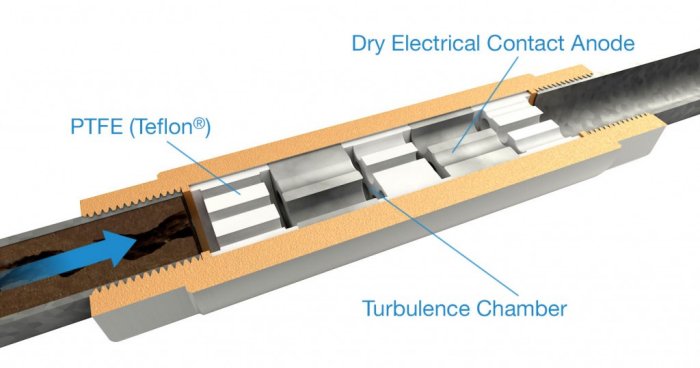

- As water flows through, cavitation within the ION ScaleBuster chamber unit produces violent pressure changes that break up bicarbonate molecules and the dielectric materials produce static effects.

- The electro-static galvanizing action of the ION ScaleBuster causes the breakdown of calcium and magnesium bicarbonates in the solution, (hardness in the water) which precipitate less soluble carbonates.

- As a result, the treated water becomes less saturated and is able to dissolve existing deposits over time.

- The combination of these effects is repeated many times. Once the salts are precipitated or removed, this action improves the flow and overall efficacy and efficiency of the piping system.

Equipment Damage, Energy Loss, & Increased Maintenance

Because the ION ScaleBuster removes existing scale buildup on pipework, valves, heating elements including hot water heaters, electrical heating elements, industrial heat exchangers, hot water pipes and tanks, less energy is required to heat the water.

Clears Existing Scale DepositsThe galvanic effect of the ION ScaleBuster provides a reducing effect on corrosion sites. By precipitating hardness, the treated water becomes less saturated and, therefore, is able to dissolve old deposits over a period of time.

The time taken will depend on several factors—the thickness of scale deposits and the distance of effected area from the installed ION ScaleBuster. The volume of water passing through ION ScaleBuster will determine the length of time taken to clean scale and corrosion deposits from the system. However, once installed, a ScaleBuster unit will commence its job immediately provided that a water flow is still possible.

Based on the unique advantages our innovative technology, ION ScaleBuster has become the choice of major firms and municipalities around the world for corrosion and scale removal in pipeworks and equipment.

- Proven worldwide for over 30 years

- Significant installed base of 300,000+ units

- Zero operating costs – requires no chemicals, magnets or electricity

- Decreases resistance in piping – reducing energy required for pumping

- Coagulates suspended particles in water to enhance filtration efficiency

- Maximizes the efficiency of heating elements

- Minimizes downtime and maintenance

- Extends operational life of metal piping and equipment

- Safe, chemical-free operation—no special handling or storage requirements

- Long-acting treatment

- Low internal flow resistance

- Less dependent on flow conditions than magnetic-based systems

- Certified for potable water by WRAS UK, ACS France, TÜV Germany/Europe, IAPMO R&T USA

- Installation flexibility – compact design simplifies retrofits

- Minimal maintenance – no mechanical moving parts to be replaced

- Lead Free (NSF/ANSI 372)

A Safe, Environmentally-Friendly Process

Unlike systems that use harsh chemicals to dissolve scale and corrosion and contribute toxic pollutants to groundwater, the ION ScaleBuster works without chemicals. Instead, it employs an electrostatic process that is planet-friendly. This reduces energy and water consumption, while reducing or, in certain cases, eliminating toxic water discharge.

Chemical-Free Flocculant

The patented construction of its PTFE (Teflon®) turbulence chambers alters the static balance within the unit. This neutralizes charged particles, causing them to flocculate, or form large clump particles that are slower to re-dissolve in the water. In normal “straight flow” systems, the flocculate particles of scale remain harmlessly in the flow of the water and are unable to adhere to the pipe surfaces. In re-circulating systems – or those that contain settlement areas – filtration or flushing is commonly used to remove these treatment by-products. Corrosion is now under control and further damage to the system and associated equipment is prevented.

Laser Particle Analysis

Sophisticated laser particle analysis was used in the development of theION ScaleBuster to determine the optimal precipitate size. The large particles produced are much slower to re-dissolve in the water, extending its beneficial treatment effects.

ION ScaleBuster technology is used around the world by major companies and institutions for its proven ability to inhibit scale and corrosion. In the process, they are saving energy and water, and minimizing the use chemicals in their cooling and production systems.

Here are just a few of the firms putting ScaleBuster to use in their operations:

- ABB

- Alstom GmbH

- Alba Infraserve GmbH

- Atmos Medizintechnik GmbH

- Bast Bau GmbH

- Bayer AG

- Bayer Oil GmbH

- Bosch Electronik GmbH

- Commerzbank AG

- Continental Teves

- Danfoss GmbH

- Daewoo Korea

- FS Karton GmbH

- Gala GmbH

- Hyundai Korea

- Japan Tobacco Ind

- Knipex

- Thyssen Krupp Nirosta AG

- Life Technologies (multiple locations, USA)

- MAN Roland AG

- Messe Düsseldorf GmbH

- Muhr & Söhne GmbH

- Municipal Buildings (AZ, CA, TX, ON)

- Hotel Adlon Berlin

- Savoy Hotel London

- Cumberland Hotel London

- The Ontario Green Schools (Canada)

- University of Calgary

- Northern Alberta Institute of Technology

- UC Davis

- University College London

- University of London

- Kings College London

- Middlesex University

- Nottingham University

- The University of Kent

- Santa Rosa College

- Fresno Pacific College

- NIH National Institute of Health Maryland

- Naval Medical Facilities USA

- VA Hospitals across USA

- Valley Medical Center (CA USA)

- Peter Lougheed Center Hospital (AB)

- MVA, Bonn

- North Star Foods (MN USA)

- Philips Semiconductors

- Pepsi Cola (multiple Plants Worldwide)

- Peguform GmbH

- Posco, Korea

- Rhienbraun AG

- YMCA

- Winsport Calgary AB

- Community Recreation Centers

- Dublin Ice Rinks

- Republic National Bank of New York

- Oxford Magnet (UK)

- The Baltic Exchange (UK)

- Calgary Stock Exchange (AB Canada)

- 99 Bishopgate (UK)

- Canary Wharf London (UK)

- Canada Square London (UK)

- PG&E (multiple facilities USA)

- Spirit Aerosystems – Nacelle (KS USA)

- Sheraton

- Doubletree

- King’s Daughters’ Hospital (IN USA)

- Abbott Labs (CA USA)

- CV Therapeutics (CA USA)

- Kaiser Foundation Hospital (CA USA)

- Sudbury Regional Hospital (ON Canada)

- Lakeridge Health Center (ON Canada)

- Books Etc (UK)

- Gap Stores

- Marks & Spencer

- Bordes

- St. Lawrence Market Toronto

- Ontario Ministry of the Environment Toronto

- Ministry of Defense of the UK (H.M.S.)

- The Cabinet Office of the British Government (UK)

- Borough of Kensington & Chelsea (UK)

- Essex County Council (UK)

- Court Houses (USA)

- US Federal Correction Facilities (prisons)

- Police Departments (USA, UK)

- Police Training Facilities (USA, UK)

- CFIA (Canadian Food Inspection Agency)

- CSA (Canadian Space Agency)

- NASA (several facilities USA)

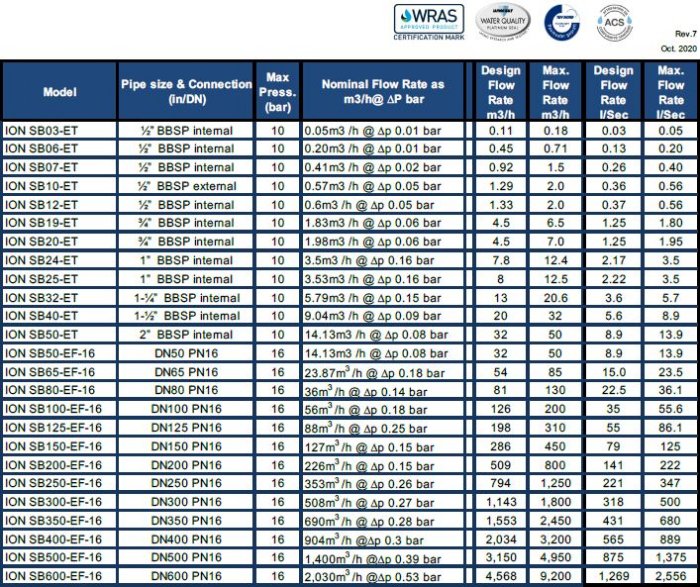

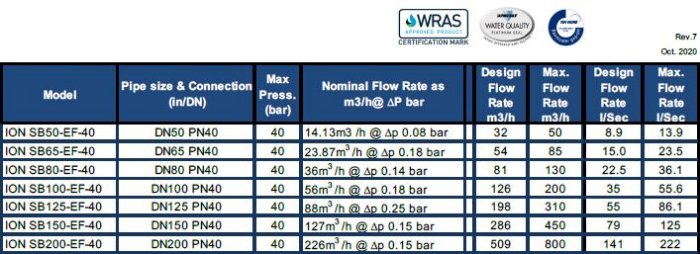

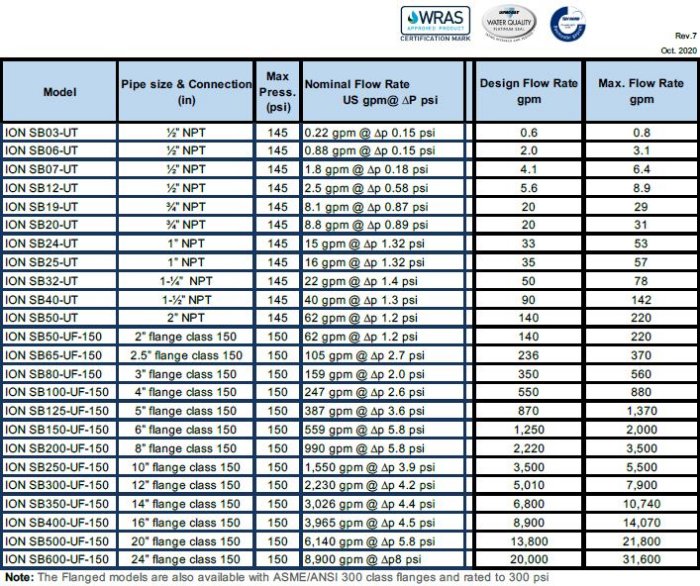

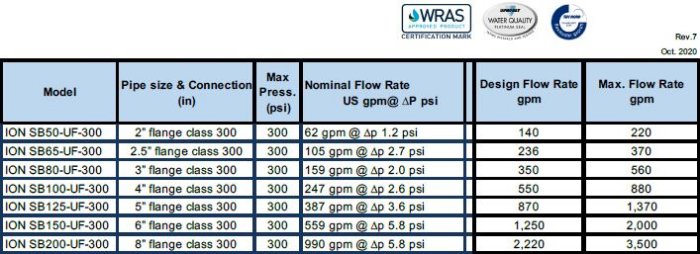

An Extensive Range of Sizes & Flow Rates

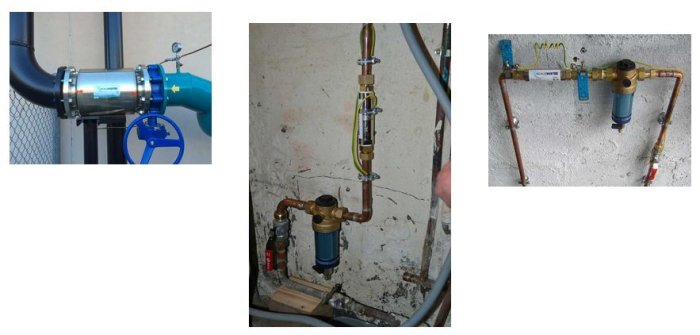

ION ScaleBuster technology is available in numerous sizes to cover a wide range of flow rates. Our models are equipped with either European (E) or North American (U) connections to address virtually any piping or equipment configuration. The durable construction of ScaleBuster conditioners allows them to provide years of reliable service inhibiting scale and corrosion without power, magnets, chemicals or maintenance.

ScaleBuster units are available with threaded connections (T) or flanged connections (F). They have been rigorously tested and certified to the high standards of the following organizations.

How To Properly Install Your ScaleBuster

The Water

An analysis of the water should preferably be submitted when proposing to use theION ScaleBuster with industrial or well water. The use of the ScaleBuster with water at a temperature over 140°F (60°C) is not always desirable. Please consult your distributor if you intend to install the ScaleBuster in a system of piping with water temperatures over 140°F (60°C) or where the values of the ‘drinking water directive’ (TVO-conductivity and/or pH values) are exceeded. There should be no significant variation in the water quality or operating conditions during usage.

The ION ScaleBuster

TheION ScaleBuster is physical device for inline installations only and must be kept wet once usage commences.

The pressure drop with proper use of the ScaleBuster is minimal. It should be noted that the flow rate of the chosen ScaleBuster should be at or above the nominal flow rate of the connected water system but below maximum flow rate as noted on the specification of the specific model. Due to the symmetrical construction of the ScaleBuster, the direction of the water flow can be from either end of the device. The model and size of ScaleBuster to be selected should be determined by the maximum flow rate demand in the system of installation. In residential, the size of the water meter will typically determine the size of the ScaleBuster.

Installation

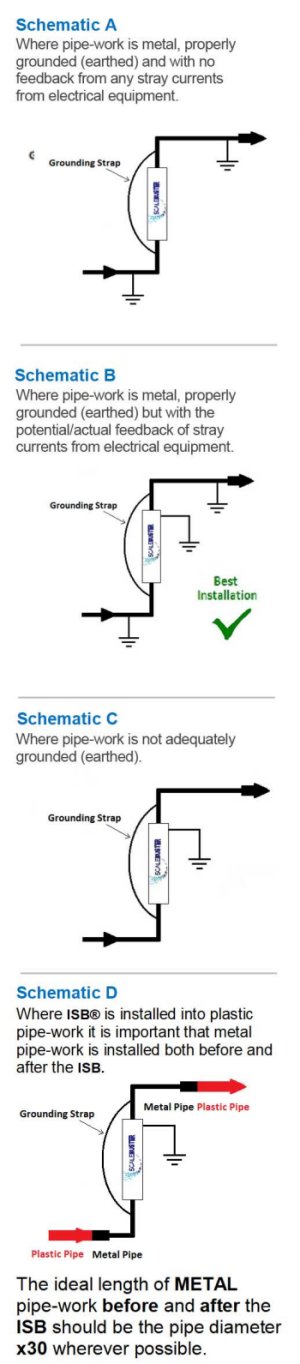

ScaleBuster Installation | Metal Pipe:

Demonstration of ScaleBuster water conditioner being installed.

To see video, please click here.

ScaleBuster Installation | Non Metal Pipe:

Demonstration on how ScaleBuster water conditioner is installed in non metallic pipe. 2 metal sections (length 30 times the pipe diameter) are required in both side of the conditioner as well as proper grounding.

To see video, please click here.

ScaleBuster Installation | Flanged Metal Pipe:

Demonstration on how the flanged ScaleBuster water conditioner is installed in a metal pipe.

To see video, please click here.

It is recommended that a company specialising in this field should install the ScaleBuster. Depending on the length and model of the device selected, a section of the piping should be removed, two compatible coupling connections installed properly and then the ScaleBuster installed.

When installing the ScaleBuster in a stainless, black or galvanized steel or copper piping system the device must be electrically bridged using suitable bonding wire. When installing the ScaleBuster in a plastic piping system pieces of piping of a metallic nature at least the length of the ScaleBuster must be inserted into the pipeline before and after the ION ScaleBuster. In these cases a grounding wire must be connected to a physical grounding point.

The ScaleBuster should be installed as close as possible to the individual pieces of equipment to ensure their protection (e.g. heat exchangers, pumps etc.).

NOTE: The Teflon tape (or liquid) doesn’t create a seal, it reduces friction so you can tighten more with the same turning force.

Torque

These are the recommended torque for the threaded ScaleBuster models:

| ½” (all models) | 65 Nm (+/- 10%) |

| ¾” (all models) | 90 Nm (+/- 10%) |

| 1” | 150 Nm (+/- 10%) |

| 1-1/4” | 240 Nm (+/- 10%) |

| 1-1/2” | 290 Nm (+/- 10%) |

| 2” | 305 Nm (+/- 10%) |

Caution! During installation in a copper piping system the ION ScaleBuster must not be exposed to the heat from soldering. The ScaleBuster must not be levered or turned against the screw joint ends or flange couplings. Pipe wrench or spanners should only be used on the couplings and never on the ScaleBuster itself. The ScaleBuster must be installed with zero potential (good grounding).

Central Warm Water Processing with a Circular Flow System

If the heating equipment, which is being protected by ION ScaleBuster, also contains a warm water circulation loop, an additional ScaleBuster, should be incorporated in the pipe work of the loop to provide protection against scale and corrosion. This ensures efficient after-treatment and enables the whole system to be protected. In case the system has multiple loops, each and every one should be equipped with one ScaleBuster.

Filter

If a fine filter is present then the ION ScaleBuster should always be installed downstream of the fine filter – even in a circulation flow system. It is recommended that a fine filter should be installed upstream of the ScaleBuster if there are problems with debris due to bad corrosion etc.

Electrical Earth Bonding

Electrical earth bonding (grounding) is essential to enhance the performance of ION ScaleBuster in addition to providing a safe continuity of earth bonding for other purposes. When plastic pipes are used be sure to bond the actual ScaleBuster to a grounding point (earth) to achieve an effective earth (ground). See Schematics for guidance on grounding.

For a successful Installation of the ION ScaleBuster

- If in doubt use a qualified installer (Check with your local ScaleBuster distributor).

- Install with the correct flanges and gaskets for the particular installation.

- Care must be taken to ensure that connecting joints requiring applied heat (Welding/soldering) must not be used in the vicinity of the ScaleBuster because the conducted heat will damage the unit’s interior, causing possible failure of the ION ScaleBuster.

- Check the orientation of the installation flanges on the pipeline is correct so as not to cause Radial Displacement of the flanges or other stresses.

- The water pressure must not be above the Max. Pressure on the ScaleBuster label (i.e., Threaded units: 145 psi (U models), 10 bar (E models); Flanged units: 150 psi or 300 psi (U models), 16 bar or 40 bar (E models). If in doubt check with your ScaleBuster distributor.

- The temperature of the water should not be higher than 140°F (60°C) for optimum performance.

- ScaleBuster will work slightly more efficiently when installed vertically.

- Always earth / earth bridge across the ScaleBuster making sure a good earth (ground) connection is achieved.

- ScaleBuster is designed for the use with potable water as well as industrial purposes.

- Ion ScaleBuster is best installed in the cold water feed supply lines. In certain instances, such as central heating, hot water returns and cooling towers, ScaleBuster should be installed in the cool end of the recirculating system, if possible.

- Check that you have a genuine ION ScaleBuster – it should carry the ISB Hologram on the label.

- Register your new ScaleBuster with the serial number (see label), invoice number and date on www.scalebuster.com. The warranty becomes void if you fail to register within 30 days from the date of the invoice.