Scaling Electrolyzer Technologies for Industry

Our team is engineering the world’s largest membrane-based electrochemical cells, operating at high current densities, to drive down the investment and energy needed for industrial hydrogen. Larger Cells and Higher Current Density Improve Output at Every Level: The idea is simple: bigger cells operating at higher current densities means more hydrogen production at every level – cell, stack, electrolyzer and plant. Our focus is on the design of plants 20MW or greater that include: Largest cells in the industry, Capability to run at current densities that far exceed any other alkaline water electrolysis technologies, Wide dynamic operating range with load shedding ability of 95% to reduce energy costs and load gaining ability to maximize H2 production

Verdagy’s technology is designed to grow with our customers. Our membrane-based water electrolysis is engineered to make it easy to scale and maintain into the future. For example, a unique cell design and architecture simplify manufacturing and reduce component count for greater reliability. Our mature approach to operations and predictive maintenance optimizes uptime. What’s more, we can easily replace key components over time as we continue to innovate, ensuring our customers have access to the most advanced technologies.

The Verdagy approach combines the three compelling economic attributes into an elegant 20MW electrolyzer and 200MW plant. First, this “eDynamic” product can rapidly change operating parameters in order to meet changing conditions, such as fuel demands of industrial processes, or to fluctuations in energy pricing. This helps to optimize facility design and ongoing operating costs.

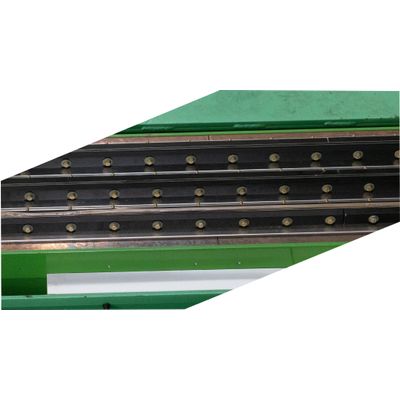

In addition, we build our electrolyzer and plant using very large active area cells with the ability to run at industry-leading current densities. Taken together, these three attributes add up to the lowest upfront capital costs and the lowest unit production economics.

While “eDynamic” is an entirely new category of electrolyzer and plant, it arises from solid industry experience and proven base technology. We know how to successfully operate our very large cell at high current densities and in highly dynamic operations. We’ve been doing this for over ten years supporting the chemicals industry with over 100,000 hours of lab and pilot plant operations. Our veteran team has been working tirelessly to design the best, most advantageous features of large cells, while designing out all the aspects that cause failures. Taken together, “eDynamic” is robust and ready-to-scale.