Paul Groth Mühlenbau GmbH & Co. KG

- Home

- Companies

- Paul Groth Mühlenbau GmbH & Co. KG

- Products

- Paul Groth - Model DRS-G - Screw Feeder ...

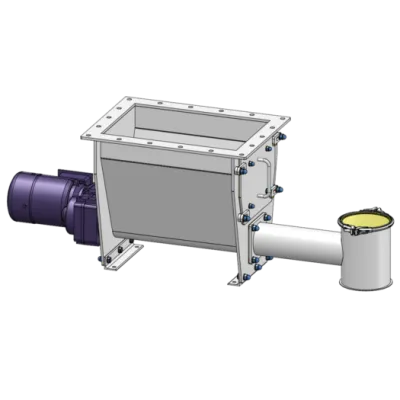

Paul Groth - Model DRS-G -Screw Feeder for Powder and Granulate Dosing

The Screw Feeder DRS-G is designed for the precise dosing of powders and granulates, offering a dosing capacity ranging from 9 to 51,000 liters per hour, adaptable to various sizes. Constructed from robust stainless steel AISI 304, it provides durability with a cleanable design, featuring pickled and glass bead blasted surfaces. The feeder includes a 450 x 300 mm inlet hopper and can be customized according to specific needs. It supports additional features such as a pneumatic shutter to prevent product trickling, a dispersing agitator for improved flow of non-free-flowing materials, and optional limit switches for level indication. The device is prepared for further enhancements like a lump breaker for crushing soft lumps and different shaft sealing options to accommodate varying temperature conditions. Its modular build allows for later upgrades and easy cleaning via a thread pull-out device. Suitable for applications requiring compliance with food safety standards, it is optimal for dry and non-sticky products.Most popular related searches

screw feeder

food safety standard

dosing screw

granulator

lump breaker

level indicator

precision dosing

temperature sensor

food safety

flow limiter

Dosing screws type DRS-G are developed for dosing of powders and granulates. The dosing capacity is between 9 and 51,000 l/h depending on the size.

Our proven modular system for dosing screws meets most requirements for dosing of powders and granulates.

They are made of stainless steel 1.4301 (V2A, AISI304) and are easy to clean.

If you have customization requests, we would like to consider them.

We would be pleased to talk about the task with you.

- Parts in contact with the product are made of stainless steel AISI 304

Sealings in contact with the product are food compatible according to 1935/2004/EG and FDA - Designed for biologically dry food and dry cleaning

- Cleaning hatch at the front plate, dosing tube dismountable

- Surfaces

outside - pickled and glass bead blasted

inside - welding seams grinded and pickled - Screw feeder with geared motor with temperature sensor for onsite frequency converter

- Progressiv thread pitch in the inlet area

- Transparent lid above the outlet or aspiration connection

- Prepared for installation of a dispersing agitator

- Design for use in the EU

- Inlet hopper with app. 20 l capacity

- Prepared for installation of a dispersing agitator

- Cleaning hatch at the front plate

- Screw shaft mounted on one side

- Screw shaft screwed in and easy to change

- Progressive thread pitch in the inlet area

- Double screw blade at the outlet for more exact dosing

- Shaft mounted geared motor in on-slip design