- Home

- Companies

- Tianzhong Machinery, Co., Ltd.

- Products

- Tianzhong - Model TZ - Screw Press ...

Tianzhong - Model TZ -Screw Press Separator

A screw press separator is highly versatile solid-liquid separation equipment. It is designed to separate solid particles from liquid or slurry by applying mechanical pressure. Its versatile application finds across various industries, such as wastewater treatment, manure management, food processing, fruit and vegetable waste management, and more. At Tianzhong Machinery, we take pride in offering a diverse range of screw press dehydrators to meet your specific needs and requirements. You can trust us to provide custom solutions for your solid-liquid separation challenges. Welcome to contact us for more information.

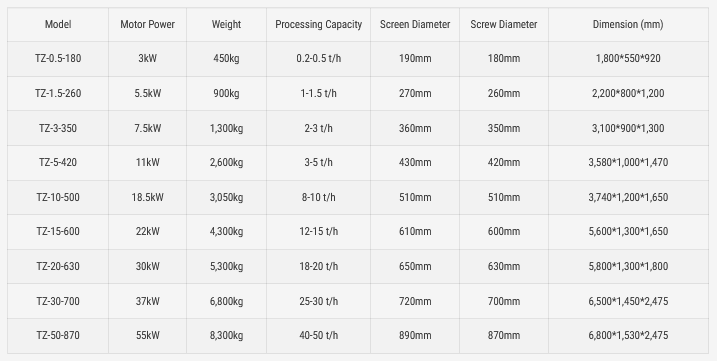

Tianzhong Machinery has single-screw press and double-screw press dehydrators for sale. In a double screw press, there are two screws installed in opposite rotational directions. This kind of machine is effective for handling materials with high fiber content, such as sugarcane, herbal residues, vegetables, and more. However, the single screw press machines have a single screw that rotates in the same direction as the shaft. They are suitable for materials with relatively lower fiber content, such as fruits, aloe vera, etc. Below are more parameters for your reference.

When choosing a screw dehydrator, consider the following tips to help you select a suitable equipment:

- Material Characteristics: You need to consider factors such as fiber content, particle size, moisture content, viscosity, and other requirements. These factors determines to choose single or double screw press, screen mesh size, etc.

- Processing Capacity: Please confirm how many tons of material you need to process per hour to determine the required processing capacity of the screw press dehydrator.

- Customization Options: Expect for screw types and screen mesh sizes, Tianzhong Machinery also offers customized options to meet your specific requirements. For example, you can choose a conveyor or shredder or other accessories according to your needs. Moreover, our equipment allows adjustments to parameters such as pressing force, moisture content, etc. to optimize the process for your particular materials.

By considering these tips, you will make an informed decision when choosing a screw press separator that best suits your needs. If you need help, please feel free to talk with us.

Screw press separators have a wide range of applications in various industries. Some of the common applications include:

Wastewater treatment:

Screw press separators are extensively used in wastewater treatment plants for dewatering sludge, slaughterhouse wastewater, and biogas slurry.

Manure management:

It is also widely employed in farms for the treatment of animal manure such as pig waste, cow dung, chicken manure, etc.

Agricultural & food processing industries:

This machine plays a crucial role in extracting juice from fruits or vegetables, such as grapes, gingers, and more. In addition, it is also used to process fruit and vegetable waste or agricultural waste, such as sawdust, crops, straw, distillers’ grains, cassava residues, grass, and more. Moreover, this machine is an indispensable pre-treatment device for drying materials. It can efficiently remove excess moisture, leading to higher production output and speed, and lower energy consumption.

Overall, screw separator is versatile equipment suitable for the treatment of various organic waste and wastewater. It offers high efficiency, simple operation, and low maintenance. More importantly, it recycles waste materials into wealth while minimizing negative environmental impacts. If you are interested, please contact us for more details!

Below is a picture showing the main parts of a screw separator machine from Tianzhong Machinery. Let’s review their functions.

- Inlet: It allows the raw material to enter the screw press. It may use a pump to ensure a consistent flow of the material mixture into the screw press, such as animal manure, biogas slurry, paper pulp, and other materials.

- Auger/Screw Conveyor: The auger or screw conveyor is a rotating spiral-shaped component inside the press. It will transport the material from the inlet to the outlet while squeezing the water out. The screw design may vary depending on the specific material.

- Screen: The screw conveyor is typically enclosed within a cylindrical screen. It allows liquid to pass through while retaining the solid particles. The screen mesh size determines the separation efficiency. The common mesh size is 0.5mm, 0.75mm, and 1mm. You can choose according to the material you process.

- Reducer: The reducer is a mechanical device that is used to reduce the high-speed rotational motion of the motor to a slower speed to suit the screw conveyor.

- Motors: There are two motors, one of which is for pump and the other one is used to drive the screw conveyor.

- Waste Water Outlet: This is where the separated liquid exit the screw press.

- Solids Discharge System: This is where removes and discharges the dewatered solid cake.

- Control System: A control system aims to monitor and regulate various operating parameters such as feed rate, screw speed, and dewatering efficiency.

- Versatile Applications: Our screw press separators can handle a wide range of materials, from high-water-content substances to high-solid-content materials. Whatever your application, we have the right model to suit your needs.

- Wide Model Range: Tianzhong Machinery offers a range of models with different capacities and specifications to meet diverse needs and requirements.

- Sturdy Construction: Our machine is made from robust materials such as carbon steel and stainless steel (SS304), ensuring durability and long-term reliability.

- Customization Options: At Tianzhong Machinery, we offer customized solutions based on your specific requirements, including the machine materials, screen mesh size, auxiliary equipment, site design, etc.

- Cost Savings: Our screw press equipment has advantages of high efficiency, low maintenance, easy operation, which can save your costs in terms of energy consumption, labor, and equipment upkeep.

- Customer Support: We provide comprehensive customer support from initial inquiry to after-sales service. Our team offers detailed information, customization solutions, and assistance in choosing the right model for specific needs. In addition, we also provide technical support, including installation guidance, operation training, spare parts availability, product updates, etc.

Tianzhong Machinery is the ideal choice for your solid-liquid separation needs. Our screw press separators excel in both performance and versatility, making them the optimal solution across various industries, from waste management to food processing. With a wide range of models available, we can cater to different scales, processing from 0.2 to 50 tons of materials per hour. Contact us now to find the perfect screw press separator for your specific application. Let’s discover the perfect solution to meet your needs.