- Home

- Companies

- IGEMA GmbH

- Products

- IGEMA - Model DLC - Self-Monitoring ...

IGEMA - Model DLC -Self-Monitoring Conductivity Limiter

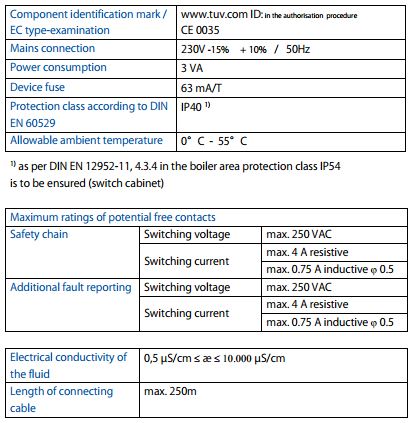

In conjunction with the DP511 level probe, the DLC self-monitoring conductivity limiter is a limiter with safety function in accordance with the Pressure Equipment Directive (PED) (special design according to Water Level 100). The product meets EC Directive 97/23/EC (PED). Conformity (CE marking) is certified in accordance with Annex III, Modules B+D (Category IV); notified body NB 0035. Regulations applied: corresponding DIN EN standards.

The DLC conductivity limiter works in conjunction with the Igema DP511 level probe on the basis of the conductive fill level method of measurement whereby the electric conductivity of the water medium is used. The conductivity of the medium is measured in µS/cm. For the secure functioning of this method of measurement a minimum conductivity of the substance to be measured is required.

Via the conductive method of measurement the conductivity of the medium is continuously determined. If a preset value is exceeded the switch point is reached and the switching procedure kicks in, e.g. switching off burner and interrupting safety circuit.

The evaluation device can supply power to the limiter probe, which is fitted in the boiler, and evaluate its signal. The serial number of the probe used must be entered in the evaluation device so that the evaluator can communicate with this probe.

With the aid of the measurement data received from the probe electronics the evaluation device determines the current conductivity in the boiler. If the condition for correct operation is met, the safety chain for the steam generator is enabled (burner can switch on). On detection (conductivity exceeded) the relay output “pre-alarm” is switched on immediately and the LED “FAILURE” starts to flash. Should this state be present for longer than the alarm delay time set, the relays of the safety chain will be switched off (safe operation mode) and the LED “FAILURE” remains permanently lit.

In the event of a fault (e.g. broken cable, probe defective, ...) the safety chain is switched of immediately. Safe operating mode during which the relay contacts of the device go into rest position, corresponds at the same time to the de-energised state of the evaluation device.

Technical basic equipment

- DLC in a plastic plug-in housing for fitting into switch cabinets

- Quick fitting with a spring catch for standard 35 mm carrier rail according to DIN EN 50022 or screw fixing on a mounting plate