- Home

- Companies

- Bannow Exports Ltd

- Products

- Bannow Boxer - Sewage Treatment Plant

Bannow Boxer - Sewage Treatment Plant

The Bannow Boxer Package Sewage Treatment Plant has been specifically designed to meet the exacting requirements of very small populations in remote areas where nutrient removal is required.

Stricter effluent standards are being introduced throughout the world. The Boxer package treatment plant has been designed specifically to meet these stricter standards and will remove nutrients down to low levels.

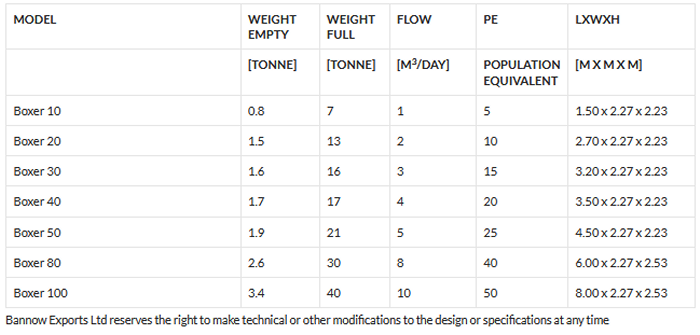

Loadings are shown below in Population Equivalent (PE) which is the equivalent of a residential population. Applications like factories or offices will have a much lower PE than the number of people working there. For hotels or game lodges the PE will be greater than the number of residents. Please contact us or our distributors to check exactly what size sewage treatment plant (STP) you require.

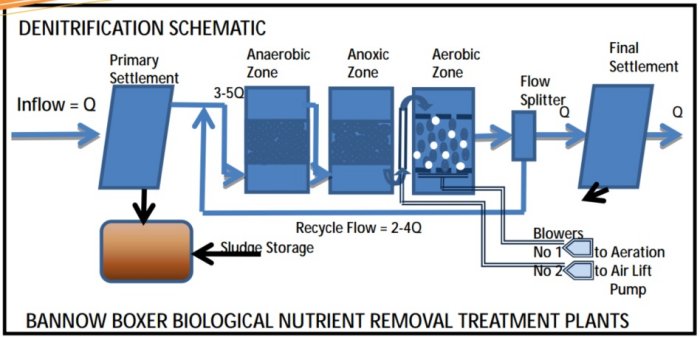

Raw effluent flows into the primary settlement zone where 75% of solids are removed using lamella (parallel) plates for more efficient settlement. This is also the sludge storage area. The settled effluent flows into the anaerobic zone which contains a plastic media onto which anaerobic bacteria can grow. This zone reduces dissolved oxygen in the wastewater as well as acting to digest solids produced in the wastewater treatment plant. Next is the anoxic zone where denitrification of the effluent occurs using a fixed media on which the denitrifying bacteria can grow. A constant forward feed flow from the anoxic to the aeration zone is achieved via an air lift pump. BOD reduction and conversion of ammonia to nitrate is achieved in this zone with media providing a surface on which the bacteria grows. There is a constant recycle between the aeration zone and the anaerobic zone. The level of recycle is between 2 & 4 times the incoming flow (recycle flow is variable depending on the concentration of the effluent and the discharge standards). Sludge is periodically removed from the aeration zone using air scour and an air lift pump to the sludge storage area. The clarifier or final settlement area uses lamella plates for efficient removal of solids and the sludge is returned to the storage area. A Saran filter is fitted to the clarifier to prevent carry-over of solids.

A Bannow Pumpwatch monitoring system is installed as standard. This will monitor performance as well as report any faults and assist with predictive maintenance.