- Home

- Companies

- Pottinger Entsorgungstechnik GmbH

- Products

- Shredder & Briquetting Press

Shredder & Briquetting Press

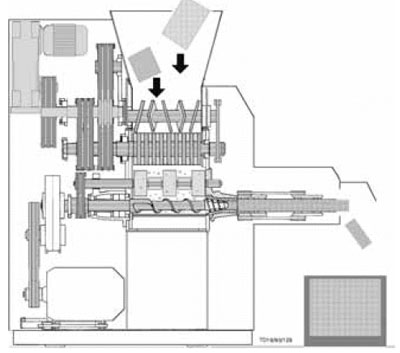

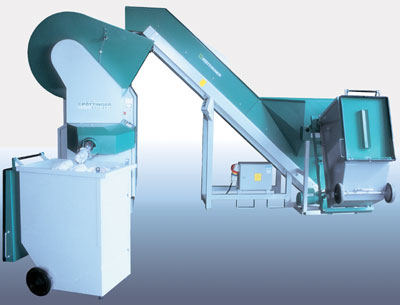

Optimal Safety: Up to 200 kg of material can disappear into the hopper every hour. The briquetting press switches off automatically once the hopper is empty. The briquetting press cuts everything to shreds. The robust, powerful blades can even handle whole files full of paper. The hopper can hold up to around 50 files.

The standard model is filled with waste paper manually and with ease thanks to a built in access platform. The briquetting press switches off automatically when you step on the platform, and switches back on again when you get off.

The briquettes are pushed along a channel straight into the stillage.

A compressor rotor can be fitted as an extra to feed even the bulkiest packaging into the shredder. Boxes or cartons do not need to be torn up before being fed into the hopper.

Briquettes packed with advantages:

Compression up to 20:1

- Ideal solution for transport logistics

- Environmentally responsible briquetting

- Paper durst is drawn up by the moisture

- Not easily flammable

- Data protection to DIN class 4

- Briquetting for paper, cardboard, dusts, fibres, aso.

- Feeding via chute

Shredding and briquetting fully automated in one operation

The briquettes possess the optimal composition for recycling.

The final disposal of the briquettes is the last step that closes the reusage cycle. The briquettes can be recycled by the paper industry as they are, or pressed into bales with other waste paper and cardboard.

The briquettes are used to make new paper and - packaging - yesterdays waste paper at the start of a new cycle.

Channel straight with assembled dumping system - optional.

A compressor rotor feed even the bulkiest packaging into the shredder.