- Home

- Companies

- Next Generation Recycling Maschinen ...

- Products

- NGR - Model A:GRAN - ...

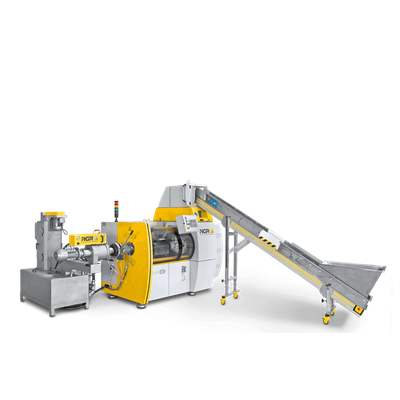

NGR - Model A:GRAN -Shredder-Feeder-Extruder Combination System

A:GRAN is the compact technology for scrap plastic products created in industrial processes of any type. The recycling machine combination focuses on high performance in a compact space.

Thanks to the system‘s minimal energy consumption and material-conserving shredder, A:GRAN can be used to achieve zero-waste production (all production waste fed back in). This means that high efficiency and implemented sustainability are the biggest strengths of this recycling solution.

Thanks to the high capacity of A:GRAN, start-up lumps are actually re-processed without any additional pre-grinding. Do you have production waste that is created intermittently? No problem! This versatile solution switches on and off quickly and easily, enabling you to work efficiently and meet the needs of the shop floor.

- Processing industrial plastic waste of any kind

- Output rate up to 120 kg/h (270 lbs/h) depending on type

- Switching on and off by a single push button

- Quick and easy start-up and shut-down at any time

Plastic waste is processed by a heavy duty shredder operating at low speed for gentle size reduction and minimal loss of material properties. In this process, pneumatic rams push the material into the shredder drum. After shredding, the material is fed directly into the extruder.

In the extruder, the material is brought to a uniform melt temperature and degassed, if necessary. All the components are positioned in close proximity to prevent oxidation of the material and to make optimal use of heat from the shredding process.

Shredder, feeder and extruder lie along one axis and are driven by a single motor. This patented combination of shredder, feeder and extruder is a feature of all units in the A:GRAN line.

In a single process step, the slow-turning shredder blades grind up the plastic waste and the shredded material is then fed continuously to the extruder.

Large, thick or bulky waste can be processed without pre-shredding as long as pieces fit into the hopper opening.

The control system provides for smooth start-up of equipment components. Restart after unplanned shutdown in less than two minutes with full hopper and full extruder

The material level in the chute is constantly measured and the feed is regulated accordingly. Conveyor can be loaded intermittently – the rest is handled by the NGR control unit

Extruder screw

Specially developed for the challenges of recycling, the universal extruder screws provide optimum melt homogeneity and process material efficiently with minimal loss of physical properties. For special requirements, our expert NGR engineers develop custom-tailored screw geometries.

All equipment functions from feeding to pelletizing are controlled automatically from the easy-to-read NGR touchscreen.

Recipes are managed in the operator control unit, which increases traceability, provides ease of use, and ensures equipment parameters are set properly.

In addition to high quality, the uniform pellet size also provides for homogeneous mixture in new material. NGR thus plays an indirect role in ensuring consistent quality in the final product.