GME Ventiduedenti - Shredder for Aluminum Scrap

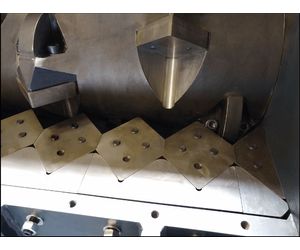

GME Recycling (Gianni Mori Engineering) finally presents its latest arrival in the world of aluminum recycling, a jewel of design and performance that promises innovation and tangible benefits in the processing of aluminum scrap of any kind. With a captivating and all-Italian name, wants to get inspired to masterpieces of Italian engineering such as the Granturismo designed by Maserati or the Roma for the Ferrari house, giving to the new shredder the name of “Ventiduedenti”. The name is inspired by the new rotor design, elliptical in shape and equipped with twenty-two blades “teeth” forged in a hardened special alloyed steel and designed to treat all types of aluminum waste with absolute precision.

the new blade design has been developed considering one of the most important topic, performance over time. Thanks to the new “QUAD-CUTTING-FACE” technology, the design utilizes all 4 blade cutting edges that can be rotated up to 4 times, for a 4 times longer life than a single edge blade design.

The new Hydraulic motor defined together with Hägglunds Bosch Rexroth has a perfect fit for the new Ventiduedenti, equipped with a modular algorithm to give tangible benefits such as the reduction of cutting peaks, less stress and wear of mechanical parts (e.g. support bearings) and hydraulics (e.g. pump and oil hydraulic circuit) for a reduced consumptions both on electricity and maintenance costs with an increased productivity (TPH).

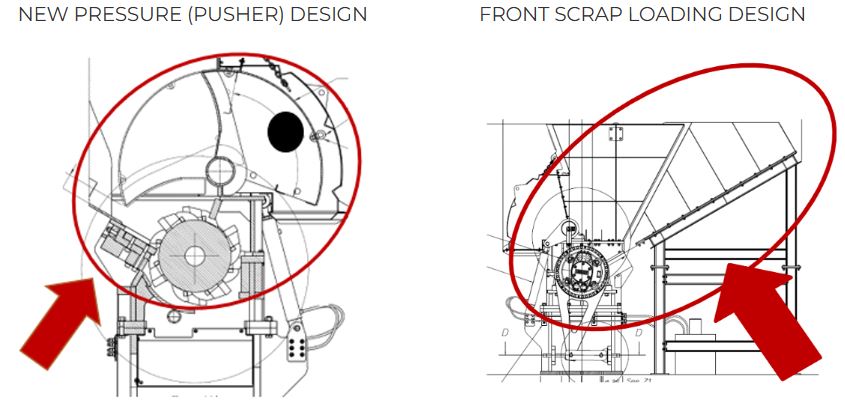

The new DESIGN WITH PRESSURE (PUSHER), avoids the annoying problem of the scrap floating on the rotor and the thickening of the scrap on the rotor itself, which therefore involves a useless waste of time and a reduced efficiency of the aluminum scrap disposal process.

The new Pusher has been designed to adapt to all types of scrap and to be able to mechanically push the scrap towards the blades, equipped with a 3-module electronic system (fully automatic, semi-automatic and manual) depending on the type of load and needs of the customer, in order to allow a cut with each stroke of the blade, without loss of time and for a perfect optimization of the material load on the shredder.

Allows to have a sliced aluminum scrap with size perfectly controlled and homogeneous. The design of the new plate called “Tegolo” has the task of standardizing the aluminum scrap during the shredding process, to manage the scrap that laid or is positioned in a non-homogeneous way at the mouth of the shredder and which would normally be discharged as it is.

The new plate, instead, acts as a “partner” controlling the part below the rotor and checks that the length of the cut profiles is homogeneous and standard, so as to have an extra element of safety on the quality of the shredder output.

The new design is also giving benefit to the brand new frontal charging station studied to facilitate the loading procedure of the material in front of the rotor to make the cut precise and continuous with the possibility of loading extra large pieces up to 7 meters in length.