- Home

- Companies

- Nantong Rongheng Environmental ...

- Products

- RH - Side Channel Blower

RH - Side Channel Blower

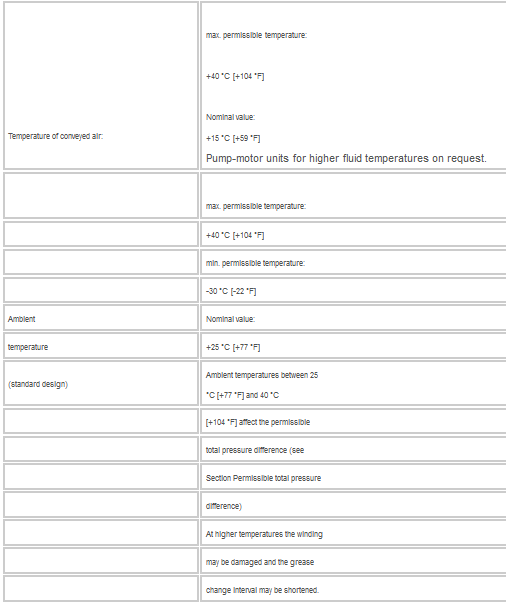

RH side channel blowers are used for air, gases and for pneumatic transport, with no material passing through the pump housing. In vacuum applications, RH products have proven their reliability for central dust extraction systems, point extraction, cooling and vacuum lifts.

In pressure settings, clean and dry blowing with air are common applications as well as aerating pools, blowing-off tanks, packaging machines and various applications in the bio- and chemical industry. Standard versions are suitable for all non-corrosive and non-flammable gases between -20° and +40°C. All versions of RH side channel blowers are extremely suitable for continuous operation.

Common uses are aeration, the pneumatic transportation of bulk goods, air supply in combustion processes, air film transportation, drying using air knives and oxidation processes. You will be familiar with these processes from industries such as water purification, cement production, thermal power stations, blast furnaces, pharmacy, food products and much more.

Mechanical damage and corrosion!

Failure to adhere to the storage conditions can lead to mechanical damage and corrosion or can shorten the re-greasing interval.

- Adhere to the storage conditions.

- The maintenance intervals of the ball bearings become shorter as the time of storage increases.

- Connect all suction vents so that no dirt or solid particles can enter.

- Turn the rotor once per year so as to avoid permanent standstill marks

Measures after long-term storage

Replace ball bearings and radial shaft seal

When the length of storage until assembly is exceeded by 4 years for the torage conditions provided in Storage:

- Replace the rolling bearing.

- Clean adjacent bearing areas for open ball bearings and re-grease.

- Replace and grease the radial shaft seal.