Sierra Instruments, Inc.

- Home

- Companies

- Sierra Instruments, Inc.

- Products

- Sierra FlowTrak™ - In-Line Flow ...

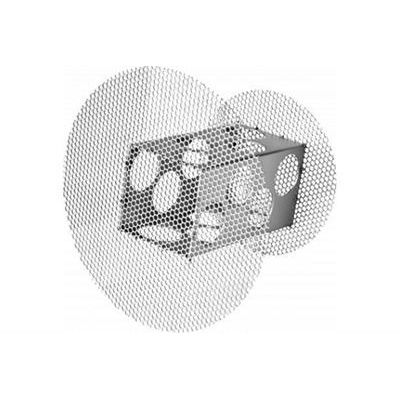

Sierra FlowTrak™ - In-Line Flow Conditioning Plates

FlowTrak is an economical solution to problems associated with monitoring flow installations where long, straight runs of piping are not available. Extensive scientific testing since the 1990s has demonstrated that this device virtually eliminates the effect of piping conditions with fewer upstream diameters than any other flow conditioning technique. And its simplicity means it is a fraction of the cost of more complex solutions on the market.

Most popular related searches

inline thermal mass flow meter

thermal mass flow

thermal mass flow meter

gas flow meter

gas flow monitoring

flow meter

flow monitoring system

mass flow metering

mass flow meter

flow profiler

The FlowTrak conditioner:

- Creates a uniform velocity profile by means of two stainless-steel, perforated elements with specific upstream and downstream spacing, perforation size and distribution

- Eliminates velocity profile distortions, swirl and temperature stratification in the flow stream

- Provides convenience and cost savings to install any gas flow meter in tough flow profile applications

Sierra welds a FlowTrak conditioner into every inline thermal mass flow meter it sells.

- Reduce upstream piping diameters to less than 3 diameters

- Use inline upstream of any gas flow meter.

- Ideally suited for point velocity insertion-type flow meters like thermal mass.

- Designed for schedule 40 pipe with 150# flanges (for other schedules, contact factory)

- Upstream element is sandwiched between two 150# flanges, along with two 1/8” gaskets

- Flange mounting bolts serve to center the screen in place.

- 316 stainless-steel construction (other materials upon request)

- Greatly reduces straight-run requirements

- Low pressure drop

- May be used in very large diameter pipes

- Designed for use with ANY point-velocity flow measurement device

- Minimizes low profile irregularities caused by elbows, valves, expansions, reductions

- Significantly reduces upstream and downstream piping requirements

- Low pressure drop

- Available in sizes for 1” to 14” schedule 40 pipe (larger sizes contact factory)

- Rugged 316 ss construction

- Easy installation using customer supplied flanges

Required straight-length upstream diameters relative to flow profile disturbance:

- One 90° Elbow: FlowTrak (1) upstream; Oricice plate (28) upstream

- Two 90° Elbows Same Plane: Flow Trak (3) upstream; Oricice plate (36) upstream

- Two 90° Elbows Different Planes:Flow Trak (3) upstream; Oricice plate (62) upstream

- Reducer - 4/1: FlowTrak (3) upstream; Oricice plate (14) upstream

- Globe Valve - Fully Open: FlowTrak (2) upstream; Oricice plate (32) upstream