- Home

- Companies

- Safe Training Systems Ltd. (STS)

- Products

- STS - Siloxane Monitor

STS - Siloxane Monitor

The STS Siloxane monitor is designed to output a total siloxane concentration in mg/m3 in gases derived from waste water treatment, food waste digestion and landfills. Understanding the levels of Siloxane in the gas allows operators to manage gas clean up systems such as activated carbon filters and regenerative filter systems. The monitor provides assurance to those exporting gas to grid that their supply is within the tolerance limit set by the grid network for Siloxane concentration.

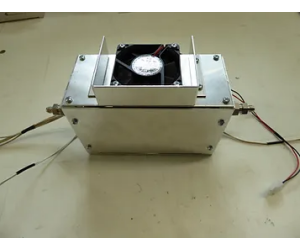

The monitor has been designed in house by STS to provide the most cost effective, reliable and convenient monitor available. STS, rather than modifying an existing device, conceptualised the idea of a monitor designed, built and tested with the sole purpose of detecting and measuring siloxanes. This enabled the design to be both results led and cost effective, resulting in the use of robust but simple design with an emphasis on practicality.

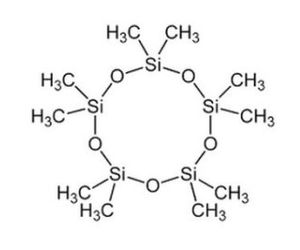

The STS Siloxane Monitor is designed to quantify siloxanes in biogas using NDIR (non dispersive infrared) technology. Siloxanes are particularly difficult to measure due to their "sticky" and persistent nature. Part of the challenge of making accurate measurements is ensuring that the measurement cell and concentrator are not contaminated after taking a reading. To alleviate this the monitor is purged with nitrogen to remove any residues and the concentrator is heated to drive off any residue which may not have been released leaving it clean for the next cycle.

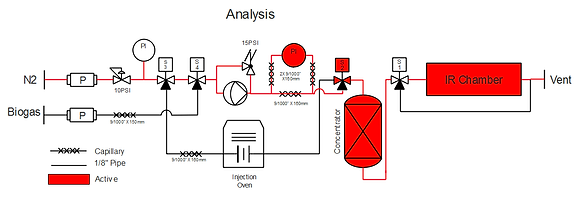

The monitor will record one reading per hour under normal conditions - of that approx 15mins are the sampling phase, 10 minutes the measurement phase and the rest is cleaning and purging ready for the next sample.

The column is then heated which releases the siloxanes from the media and they are carried by a N2 carrier gas into the measurement cell. The cell comprises a Infrared source, filters and an pyroelectric detector mounted behind specialised windows. As the carrier gas passes through the cell the siloxanes cause absorbance of the IR signal so the received signal by the detector falls and produces and equivalent voltage drop. This is recorded and processed to produce a mass of material which when calculated with the sample volume produces a reading in mg/m3.

The monitor produces a total siloxane reading which is the sum of the various species from L3 through to D6. The unit is usually calibrated using either D4 or D5 dependent on the site as these tend to form 80%+ of the siloxanes seen and are also the most damaging being the larger molecules.