- Home

- Companies

- Yokogawa Fluid Imaging Technologies, ...

- Products

- FlowCam 5000 - Single Objective ...

FlowCam 5000 - Single Objective Particle Shape Analyzer

Experience rapid high-resolution imaging, data acquisition, and analysis of microparticles. FlowCam 5000 flow imaging instrument is an economical, high-value solution for monitoring particles in the 3 µm to 300 µm size range for research, educational, and commercial applications.

FlowCam 5000 is a flow imaging microscopy instrument targeted to your specific needs for a wide range of applications. Its compact footprint allows for flexible use in a variety of settings. Accommodate small to large sample volumes for routine and specialized particle shape analysis, monitoring, and research.

Experience superior image quality and image-based measurements that yield statistically relevant data.

Is FlowCam right for you?

- Get in Touch

Tell us about your application and particle characterization needs.

- Have a conversation

We`re happy to set up a call to discuss the proper FlowCam configuration for your application.

- We`ll send you a quote

We`ll follow up to discuss the quote and can set up a seminar, demonstration, or sample analysis.

- Automate your data collection with a fast, accurate, and easy-to-use alternative to manual microscopy

- Analyze tens of thousands of particles per minute

- Go beyond size and count to analyze shape and type of your particles

- Correlate morphology information with material performance

- Characterize microparticles with as little as 250 µL of sample

- Save time and resources with an instrument optimized for your application

- Particle size range: 3 μm to 300 μm

- Magnification: Single objective (Select 4X or 10X or 20X), manual focus

- Minimum sample volume: 250 μL

- Sample flow rate: up to 1 mL/min, configuration specific

- Camera type: High resolution (1920x1200 pixels) CMOS. Color.

- Easy-to-use instrument with fully integrated VisualSpreadsheet software

Flow imaging microscopy, also referred to as dynamic image analysis, is a solution-based technique to capture subvisible and visible images of particles and microorganisms in a microfluidic channel under flow.

- A sample is manually or automatically loaded into the injection port

- A high-precision syringe draws the sample into an optical flow cell

- A fluidics sensor initiates data acquisition

- A high-speed camera records images of the full width and depth of the flow cell as the sample flows through the optical field of view

- Particle images are segmented from the camera images and captured in real-time as they flow through the flow cell

- Data is further analyzed, grouped, and filtered post-acquisition

In FlowCam 8400 and FlowCam Cyano, fluorescence excitation allows FlowCam to capture particle images whenever a fluorescing object is detected in the flow cell.

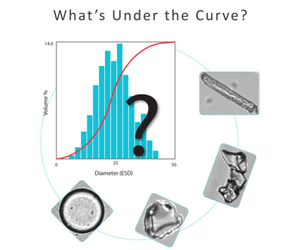

One of the key advantages of flow imaging microscopy with FlowCam is that particle measurements are calculated directly from an image of the particle. Since flow imaging microscopy is designed with fixed optics at known magnifications, distance measurements on the image can be directly converted to real distance measurements on the object. Flow imaging systems do not have to make any assumptions about a particle’s size and shape because they measure multiple particle properties directly from an image.

Other particle analysis systems, such as light obscuration, laser diffraction, and light scattering, need to make assumptions about the physical dimensions of the particle. These techniques measure a signal proportional to a physical dimension and convert that signal to a value representing the number of particles and corresponding particle size distribution in the sample. In addition, many of these analytical techniques only measure ensemble (bulk) properties, i.e., the properties of the overall population distribution.

The ultimate benefit of performing flow imaging microscopy with a FlowCam imaging system is that you can visualize single particles and calculate desired sample properties based directly on individual particle images.