- Home

- Companies

- NEO Monitors - a Nederman company

- Products

- NEO Monitors LaserGas - Model II SP - ...

NEO Monitors LaserGas - Model II SP -Single Path Monitor for In-Situ Measurement in Stacks

LaserGas™ II Single Path uses a non-contact, also known as in-situ optical measurement method, which is suitable for the measurement of a variety of gases and working conditions, and even the measurement of two gases. Laser Gas™ II SP has obtained various Ex certifications including IECEx, ATEX, CSA. The detector is not affected by pollutants and corrosive gases and does not require daily maintenance. Since there is no need for sampling pretreatment process, the reliability of measurement is further improved and the error caused by the pretreatment process is eliminated. Just connect the power and signal cables, and the purge system, and the analyzer can perform real-time measurements.

LaserGas II SP is designed for in-situ measurement in stacks, ducts, or reactors with typical path lengths in the range 0.5 to 20 meters. By-pass and extractive configurations are also possible. The monitors’ compact design comprises the transmitter unit with laser module; collimating optics, and main electronics and the receiver unit with focusing lens, photo detector and receiver electronics.

- Response time down to 1 second

- No gas sampling: In-situ measurement

- No interference from background gases

- Applicable for many process conditions:

- high/low temperature

- high dust

- corrosive gases

- Line measurement, integral concentration

- over the full stack diameter

- ATEX and CSA certified

- TÜV, MCERTS, GOST approved

- technology

- Integrated span check option available

- Suitable for harsh environment

- No zero drift

- Stable calibration

- Long OPLs

LaserGas II SP is designed for reliable and fast measurement of all kinds of gases in any environment, most typically:

- Chemical industry

- Petrochemical industry

- Metal industry

- Power plants

- Waste incinerators

- Cement industry

- Automotive industry

- Scrubber technology

- Glass industry

- PVC production

- Pulp and paper

- and more

- In-situ monitoring

- Highly reliable real time analyzer

- Low maintenance cost

- Reduce emission to the environment

- Easy to install and operate

- Reduce daily operation costs

- Optimize process

- Well proven measurement technique

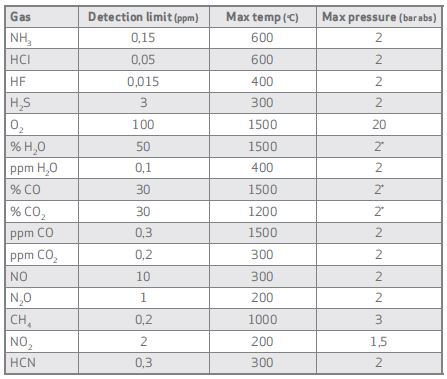

Specifications

- Optical path length: Typically 0.5-20m

- Response time: 1 – 2 sec

- Accuracy: Application dependet

- Repeatability: 1% of range (gas & application specific)

Environmental conditions

- Operating temperature: -20 ºC to +55 ºC (special version up to +65 ºC on request)

- Storage temperature: -20 ºC to +55 ºC

- Protection classification: IP66

Inputs / Outputs

- Analog output (3): 4 - 20 mA current loop (concentration, transmission)

- Digital output: TCP/IP, MODBUS, Optional fibre optic

- Relay output (3): High gas, Maintenance Warning and Fault

- Analog input (2): 4 – 20 mA process temperature and pressure reading

Ratings

- Input power supply unit: 100 – 240 VAC, 50/60 Hz, 0.36 – 0.26 A

- Output power supply unit: 24 VDC, 900 – 1000 mA

- Input transmitter unit: 18 – 36 VDC, max. 20W

- 4 – 20 mA output: 500 Ohm max. isolated

- Relay output: 1 A at 30 V DC/AC

Installation and Operation

- Flange dimension alignment: DN50/PN10 or ANSI 2’’/150lbs (other dimensions on request)

- Alignment tolerances: Flanges parallel within 1.5°

- Purge flow: Dry and oil-free pressurised air or nitrogen 10 - 50 l/min (application dependent)

Maintenance

- Visual inspection: Recommended every 6 – 12 months

- Calibration: Check recommended every 12 months

- Validation: In-situ span check with optional internal cell (application dependent)

Safety

- Laser class: Class 1 according to IEC 60825-1

- CE: Certified.

- EMC: Conformant with directive 2014/30/EU

Explosion protection (optional)

- IECEx/ATEX zone 1:

- II 2 G Ex px IIC T5 Gb

- II 2 D Ex p IIIC T64°C

- Db

- Laser zone 1:

- II 2 G [Ex op is T4 Gb]

- IIC

- IECEx/ATEX zone 2:

- II 3 G Ex nA nC op is

- IIC T4 Gb

- II 3 D Ex td A22

- T100°C

- Laser zone 0: II 1 G [Ex op is T6 Ga]

- CSA:

- Class I, Div. 2, Groups

- A, B, C and D; Temp.

- Code T4; non-incendive

Dimension and weight

- Transmitter unit: 405 (plus 65 for purge unit) x 270 x 170 mm, 6.2 kg

- Transmitter unit: 405 (plus 65 for purge (Ex version) unit) x 270 x 310 mm, 7.9 kg

- Receiver unit: 355 (plus 65 for purge unit) x 125 x 125 mm, 3.9 kg

- Power supply unit: 180 x 85 x 70 mm, 1.6 kg