- Home

- Companies

- Suzhou Famous Machinery Co., Ltd.

- Products

- Famous - Model SXR Series - Single ...

Famous - Model SXR Series -Single Shaft Shredder for Soft and Rigid Materials

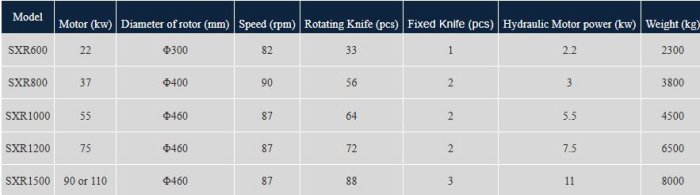

The SXR series single shaft shredder is engineered to facilitate efficient recycling of a diverse array of materials,including plastics, paper, fibers, rubber, and organic waste.Designed to meet varying customer requirements such as input and output size, the shredder can be tailored for customized applications.It features an advanced Siemens microcomputer control system that automates start and stop functions and integrates automatic reverse sensors that offer protection against overloads and jams. The model`s rotor and blades, made from high-grade D2 and carbon steel, ensure durability and effective material shredding. The hydraulic system allows for adjustable pushing speeds,enhancing operational efficiency. Available models, ranging from SXR600 to SXR1500, offer capacities between 300-3000 kg/h. Real technical specifications may vary based on specific material processing requirements.The machine is designed to process various materials such as PPR pipes, HDPE, PET fibers, and more.

The SXR series single shaft shredder is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, fiber, rubber, organic waste and a wide variety of materials. As per our customers' requirements, such as the input size of the material, capacity and the final output size etc, we could work out a suitable proposal for our clients. After being shredded by the machine, the output material could be used directly or go into the next step of size reduction. With the function of Siemens microcomputer control system, it is possible to control automatically start, stop, automatic reverse sensors to protect the machine against over loading and jamming. The single-shaft shredder is used to recycle plastic, paper, wood, fiber, cable, rubber, home appliance, light steel, municipal solid waste, etc. It is ideally suited for the reduction of a wide range of different materials.

- Rotary shaft: The rotary shaft made by high quality carbon steel, anti-worn

- Rotor blade: The rotor blade made by D2, fixed on the blades holder by screw easy to remove and maintenance, blade can use 4 times when the blade worn after using long time

- Fixed Blade: The fixed blades are movables to adjust and longer time use . Using D2 material, USA Standard, HRC 58-59 more better than SKD-II, We also can use DC53 material.

- Screen: the screen use 10mm thickness carbon steel made, with 40-100mm screen, the flakes will easy shredding and down

- Hydraulic pump station: Oil cylinder effective working. Pushing speed is adjusted by manual

- Contactors: Use Siemens/Schneider brand in us control system

- PLC: Use Siemens PLC for shredder machine. Automatic control rotor shaft positive, negative rotary

- Shredding Process:

- The hydraulic ram pushes the material against the rotor at a pre-set speed.

- The material is shredded by the rotor teeth.

- The hydraulic ram maintains the pressure against the rotor, maximizing output of shredded material.