- Home

- Companies

- ISVE S.p.A.

- Products

- ISVE Recycling - Model MR 17-40 - ...

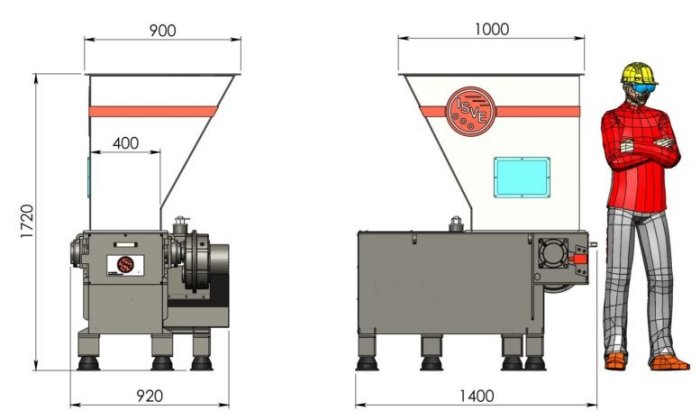

ISVE Recycling - Model MR 17-40 -Single-shaft Shredders

The MR 17-40 single-shaft equipped shredder is particularly suitable to shred small wastes with high resistance. A hydraulic control unit allows driving the pusher drawer. Thus, the product to be grinded is pushed towards a tools-holder rotor causing its crushing. Thanks to a screen it is possible to select the final dimension of the shredder material.

- power installed on the rotor:7,5 kW (10 HP)

- power of the hydraulic control unit: 0,75 kW (1 HP)

- drive:by belts

- number of rotors: 1

- rotor diameter: 170 mm

- rotor length: 400 mm

- number of reversible tools: 12

- n° of usable tools sides: 4

- average number of rotor revolutions per min.: 95

- weight: 800 kg

- production: 80-150 kg/h

- safety devices: emergency stop, drawer reversal system

- manufactured according to EC standards

- loading belts;

- interchangeable hopper;

- interchangeable screen;

- shredded material packaging systems;

- refiner for timber and plastic (for sizes lower than 14 mm).

Small sized multipurpose machine suitable for shredding wide range of waste materials.

It can be introduced into a line to operate in continuous working. Recommended for shredding pieces of wood, plastic material, paper, confidential documents, sheets, rubber pieces, etc.

- Strong welded framework;

- Support for barrel roller bearings with sealing system against dust and liquids;

- High thickness rotor with diameter of 170 mm and length of 400 mm. It is equipped with 12 tools-holder plates and 12 high alloyed anti-wear tools usable 4 time;

- Adjustable counter-blades made in very alloyed anti-wear steel;

- Pusher drawer with hydraulic driving with 350 mm of usable run;

- Pulleys and belts drive system to avoid mechanical damaging due to rotor vibrations;

- N° 1 motor of kW 7,5 for rotor activation;

- N° 1 motor of kW 0,75 for hydraulic pump with thermostat for oil and cooling radiator;

400X400 mm cutting chamber; - Welded-sheet metal hopper for top loading;

- Interchangeable screen establishing the size of the shredded material.

- Electric switchboard complying with CEE standards equipped with torque limiting device which inverts the direction of the pusher drawer if the work load of the machine exceeds the set value;

- Main internal board (LOGO SIEMENS) for the control of all the plant peropheral units;

- Emergency control functions for stopping the system.

The production of shredded material varies according to the type of piece to be grounded and the size of the grounded item required. On an everage it is possible to produce between 80 and 150 kg per hour.

- Made to Ce standards.

- Interchangeable screen establishing the size of the shredded material (diam. 14-16-20-25-30-35 mm).

- Collection drawer for ground material

- Upper hopper closure with side window equipped with rubber straps to prevent material from escaping during grinding.

- Rotor protection tile (prevents materials in the hank from overloading the rotor).

- Shredder stop software in case of overloading of the separation system / refiner mill.