- Home

- Companies

- Yangjiang Machinery Manufacturing Co., ...

- Products

- Single Stage Centrifugal Extractor with ...

Single Stage Centrifugal Extractor with SS304 Stainless Steel Material

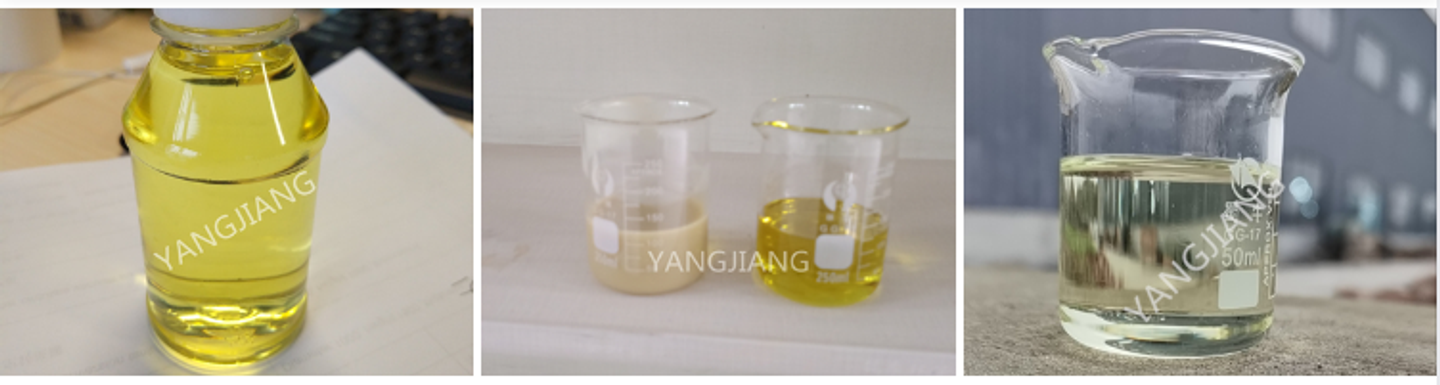

Centrifugal Extractor is a new type, fast and highly efficient liquid-liquid extraction separation equipment,which using the motor driven drum to reach high speed, the densities of different and not mutually mixed solution of two liquids in drum or blade rotation shear stress under complete mixing and mass transfer, and in high-speed rotation drum of centrifugal force under the action of rapid separation.

The centrifugal extractor combines the functions of extractor and separator with many uses. This extractor is uniquely designed, small and compact, combining the function of mixing and separation. Figure 1 is structure diagram of centrifugal machine, centrifuge chamber, the drum, and many other important design features including fluid passages can be seen in the Figure 1. Two immiscible solutions of different densities are pumped into the extractor through two entrances respectively, and then rapidly mixed in the gap between the drum and the shell, and the mixed liquid enters the drum through the inlet at the bottom of the drum, and the accelerated heavy phase is threw to the lateral side of the drum. the light phase remains on the inside of the heavy phase, the two-phase interface is between the light phase outlet and the heavy phase underflow channel, and the heavy phase underflow channel is in the upper part of separation zone that composed of heavy phase enthalpy. Figure 2 is the geometric and physical drawings of centrifugal machine.

- Separation: Direct feed minimizes the shear forces of the mixed liquid stream, thereby increasing the efficiency of the separation. The mixed liquid enters the extractor directly from the bottom inlet of the rotary drum, is centrifugally separated by the rotating drum, and enters the separation zone, and the separation is continuously performed.

- Extraction: Two-phase liquid enters the extractor from the inlets of both side of the extractor and mixes in the annular gap between the drum and the shell, usually it reach equilibrium in a matter of seconds. The special structure inside the annulus optimizes the mass transfer effect. The separation is continuously performed inside the drum.

- In-situ cleaning: can realize the liquid/liquid centrifugal extractor disassembly-free cleaning function.

- Multi-step operation: Each centrifugal extractor represents a theoretical stage. A separation system is composed of a series of centrifugal extractors, which can realize multi-step countercurrent or transverse flow extraction (Figure 3).

Centrifugal extractor, also as know as Liquid-liquid centrifugal extractors or centrifugal contactor, which has been used widely in industries such as the pharmaceutical, fine chemical, food products, nuclear etc.

- Oil industry: lubricating oil extraction, diesel desulfurization and so on.

- Pharmaceutical industry: such as used for extracting ethyl acetate, methylene dichloride, normal butanol, choroforom or extracting the Chinese traditional medicine.

- Food industry: extraction and separation of lactic acid and citric acid fermentation broth, edible oil, food pigment etc.

- Environmental protection industry: used single-stage or multistage extraction and reverse extraction to treat wastewater with phenol or acid, printing and dyeing wastewater (H acid, T acid, etc.), DMF wastewater, naphthalenesulfonic acid wastewater, etc.

- Oil-water separation or extraction for marine sewage, groundwater or separate organic solvent from the water.