- Home

- Companies

- Andritz AG

- Products

- Andritz - Model ACP Series - ...

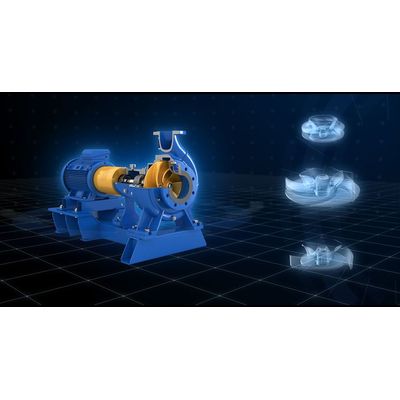

Andritz - Model ACP Series -Single-Stage Centrifugal Pump

ANDRITZ single-stage centrifugal pumps from the ACP are available in a highly wear-resistant, open impeller design. Thanks to their low axial thrust and open channels, these pumps are suitable for conveying many different media. Depending on the impeller design, they can convey slightly contaminated and contaminated media with some solids and content with consistencies of up to 8%. Equipped with our innovative SMARTSEP degassing system an additional separation impeller acts as an integrated degassing system and removes gas from the media and conveys fibers reliably back to the pump at the same time. Thus, operating as processes pumps, they cover a wide range of applications in the pulp and paper, mining, offshore, power, food, and chemical industry. Additionally, ANDRITZ single-stage centrifugal pumps can also be used in water supply, waste water treatment, desalination plants, and irrigation as well as drainage.

A modular system ensures high availability, enables the use of proven components and reduces the number of spare parts to be held in stock. ANDRITZ centrifugal pumps from the ACP series can be delivered with an Industrial Internet of Things integrated base. For more information on our single-stage centrifugal pumps from the ACP series please have a look at our brochures in the sidebar or contact us directly.

ANDRITZ SMARTSEP has been specially designed for high gas content and stock suspensions of up to 8%. An additional separation impeller acting as an integrated degassing system removes gas from the media and conveys fibers reliably back to the pump at the same time. Thus, no additional vacuum pump is needed. The controlling of the degassing valve becomes very easy. When the pump is running the valve is open, but when the pump is not running the valve is closed.

- Maximum efficiency of up to 90%

- State-of-the-art NPSH behavior

- Part load behavior better than industry benchmark

- SMARTSEP degassing system

- Reduced number of spare parts to be held in stock

- Design: single-stage, single-flow, open impeller

- Consistency: up to 8%

- Head: up to 190 m

- Flow rate: up to 9,000 m³/h

- Pressure: up to 40 bar

- Temperature: up to 200° C

- Efficiency: up to 90%