S.K Euromarket - Separation & Clarification System

Our products portfolio includes a number of systems that remove particles, fats, oils, grease and other impurities from water or wastewater by applying physical or physic-chemical processes. These systems incorporate the principles of our systems design philosophy: low ownership cost, limited space requirements, long lasting and reliable performance.

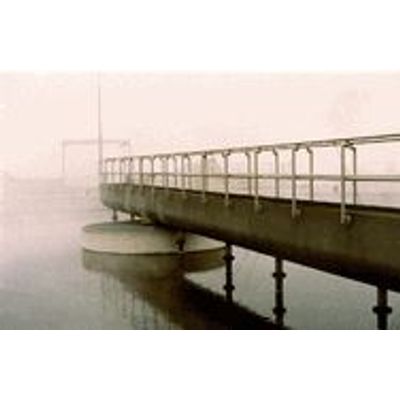

- Circular gravity clarifiers. Designed to remove particles and reduce the level of suspended solids. They employ a rotating bridge for sludge and scum removal and peripheral overflow system

- Rectangular clarifiers. Designed to serve greater capacities than circular ones while requiring less space these systems are very popular for suspended solids removal. Sludge and scum are removed with use of chain scraping system

- Lamella plate settlers. Inclined plates (lamella) are used in these systems in order to increase the basin settling area. This results in a substantial reduction of the overall footprint of the system.

- Dissolved air flotation (DAF) units. Designed in circular or rectangular arrangements with or without integrated plate settlers, DAF units are an excellent solution for separating solids and other liquids from water or wastewater.

All components, pieces of equipment and materials such as pumping units sourced by reputable international manufacturers with whom we have long term partnerships.

Wastewater and water are never single-phase fluids. They have the primary phase, which is pure water, and other phases, which could be solids (e.g. sand), or other liquids (e.g. fat, oil and grease). Any effort to physically separate these phases and extract pure water falls under this category of processes.

Some basic examples of separation and clarification are the following:

Screening

Screening is a fundamental process for removing particles from liquids. The basic concept of this process is very simple. Raw water passes through a screen, which has openings of predetermined aperture. As a result, only particles smaller than a certain size are let through the screen.

However, the effectiveness and efficiency of a screen is heavily dependent upon the mechanism of screen removal and its ability not to clog.

Depending on the flow, the concentration, type and size of the particles one may choose from a variety of screening materials, aperture sizes, opening shape, self or manual cleaning mechanisms etc.

Sedimentation by Gravity

Sedimentation is probably the most common waste and wastewater treatment process. It is defined as the separation of a suspension into a clarified fluid and a more concentrated suspension.

A sedimentation process is designed to remove a majority of the settleable solids by gravity. Sedimentation is an efficient process and it gets more successful if it is used in conjunction with proper coagulation and flocculation.

A circular clarifier with a coned bottom is one of the most proven and popular designs. Sediments are easy to remove from the bottom and the clarified water overflows to other subsequent process stages.

Sedimentation in Plate Settlers

Inclined plate (lamella) settlers represent an advancement over settlers based on sedimentation by gravity. Plate settlers are also clarification devices designed to have the clarification effectiveness of a large conventional clarifier, but in a much smaller footprint.

A plate settler makes use of plates made of plastic or metal that are installed inclined at an angle of approximately 55 degrees. The inclined design results in an expanded surface area available for settling.

Prior to entering the settler, water or wastewater goes through coagulation and flocculation. When entering the settler, accumulated solids flow down the inclined plates while clean water remains on top and is transferred to other subsequent process stages.

Dissolved Air Flotation (DAF)

Dissolved air flotation is an intelligent process that clarifies wastewater (or other water) through the removal of suspended matter such as oil or solids. The clarification is accomplished by dissolving air in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank or basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

DAF units are widely used in treating industrial wastewater effluents from oil refineries, petrochemical and chemical plants, food processing plants, pulp and paper industries, general water treatment and other industrial applications.