- Home

- Companies

- In-Situ Process

- Products

- Partech - Model SludgeWatch Ultra - ...

Partech - Model SludgeWatch Ultra -Sludge Blanket Detection

The SludgeWatch Ultra utilises the industry accepted look down ultrasonic or `sonar` method of detecting and tracking the interface between sludge and water in water, wastewater and industrial effluent settlement tanks and clarifiers. The easy to use system has been specifically designed for these applications and makes use of an easy drop down menu structure to allow hassle free site configuration. The self-cleaning transducer can monitor the interface in applications where the sludge has a density of 0.5% or more. The cleaning wiper operates automatically to remove dirt and air bubbles that can interfere with the measurement.

By monitoring the position of the sludge/water interface the user can make process adjustments to ensure that their plant is operating at the optimum efficiency whilst ensuring that water quality is preserved. If a blanket is allowed to rise too high in the tank there is a danger of carry-over to the effluent channel or the next processing stage, additionally strain may be placed on the scrapper mechanism. If there is too little sludge in the tank the settling process cannot work effectively, this leads to problems with sludge processing, returned sludge concentrations and again carry-over to the effluent channel.

Automated sludge blanket detection removes the need for time consuming manual checks, ensuring reliable process control everyday and during unexpected weather or load conditions.

The easy to use system has been specifically designed for these applications and makes use of an easy drop down menu structure to allow hassle free site configuration. The monitor provides all the setup and diagnostic information required to get the best performance out of the system.

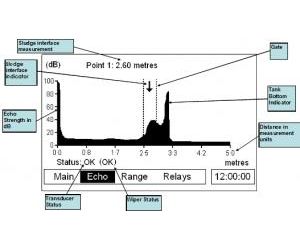

The screen image shown to the right demonstrates the depth of information that is provided. Typically a monitor that is showing a wide ‘gate’ is indicating that the settlement process in not functioning well.

Advanced echo processing algorithms allow the monitor to cope with variations in sludge density, material that is floating in the tanks and moving scrappers arms.The monitor can operate two transducers, allowing two tanks to be controlled from a single system.

The SludgeWatch Ultra transducer incorporates a fully automatic cleaning blade. Cleaning of ultrasonic sensors in sludge blanket monitoring applications is vital to ensure that air bubbles and debris does not build up on the transducer surface.

The cleaning mechanism on our transducer has a 0.2 mm clearance between the blade and transducer face, this avoids wear on either surface increasing the life of the system.

- Final Settlement Tanks

- Clarifiers

- Primary Settlment Tanks

- Self Cleaning Sensor

- Low Cost of Ownership

- Continuous Output

Physical

- Dimensions (hxwxd) : Transmitter: 235 x 184 x 120 mm

- Transducer: Ø78 mm x 185 mm long

- Weight : 1 kg

- Protection Class : Transmitter: IP65

- Transducer: IP68

- Enclosure Material : Transmitter: Polycarbonate, Flame Resistant to UL94-5V

- Transducer: Black Valox 357 with a 316 Stainless Steel Wiper Blade and Shaft

- Cable Entry : Knockouts for 5x M20, 1x M16 in base and 4x PG11 at rear

Electrical :

- Power Supply : 100 to 240 VAC 50/60 Hz, 22 to 28 VDC

- Power Rating : 14 W maximum, typcially 11W

- Transducer Cable Length : 10 metres standard, 200 metres maximum

Environmental Data :

- Operating/Storage Temperature : -20 to 50ºC

- Location : Indoor/Outdoor

User Interface :

- Display : 192 x 128 pixel illuminated graphical dispplay

- Keypad : Integral Keypad with menu navigation keys

- Units of Measurement : %age Depth

Output Signals :

- Analogue Outputs : 2x 0/4-20 mA, max load 1000 ohm

- Relays : 6

- Contacts : SPDT, 5A @ 240 VAC

- Communication Bus : RS485 Modbus RTU/ASCII or Profibus DPV0 or V1

- Principal of Operation : Ultrasonic

- Accuracy : 0.25% of the measured range or 30 mm (whichever is the greater)

- Resolution : 0.25% of the measured range or 10 mm (whichever is the greater)

- Maximum Range : 10 metres

- Minimum Range : 0.3 metres