- Home

- Companies

- ATB Water GmbH

- Products

- AQUAmax - Model Basic / 15 m 1-16 PT / ...

AQUAmax - Model Basic / 15 m 1-16 PT / 15 m Cable -Small Sewage Treatment Plant

For new installations according EN 12566-3 and for retrofitting of existing plants for the operation of a full-biological SBR plant. The plant is pre-assembled and approved by the German building authorities and can be assembled and installed into the designated tanks with a few manual operations.

The equipment consists of:

- 1 supporting frame made of PE

- 1 submerged aerator AQUA 5 / 230 V / 50 Hz

- 1 submerged pump ATBlift 2 / 230 V / 50 Hz

- 3.5 m clearwater hose DN 25

- 1 electronic control unit / 230 V / 50 Hz

- 1 sampling bottle

- 1 set assembling material

- base unity made of recyclable material

- height adjustable frame for adjustment at various tanks and PT-figures

- feeding pipe with ball valve replaces one pump

- automatic pump flushing prevents from sludge output

- observation of all German effluent classes (C, N and D) by biological processes

- highly effective economy mode in case of reduced water inlet

- easy handling control unit

- electric wiring factory-installed and sealed by casting resin, plug-ready connection

- further operation in case of failure because of single fused aggregates

- battery buffered alarm signal in case of power failure

- quick coupling of the pumps and the aerator supports an eventual exchange

- Secure operating in case of overload and underload

- Floating switch with 15° switching angle

- under voltage signaling UVS

- external alarm connection possible

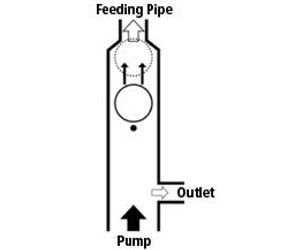

- Due to the patented ball technology, the AQUAMAX® BASIC requires one pump less than conventional SBR systems.

- This means: less electrical connections, less risk of failure, more safety.

- The principle: When one pump starts, water enters the feed pipe via a robust special valve. Depending on the pumping time, this alternates between filling / sludge discharge and discharge pumping.

- Short pumping: Initiates the filling phase of the SBR tank. Long pumping: The special ball closes the feeding or filling pipe tightly after a few seconds; the water now reaches the clear water drain.

- In this way, a large, heavy pump - i.e. an electrical unit - is completely replaced by a small ball.

- Of course, the AQUAMAX® is also patented: EU patent: 04 010 152.9

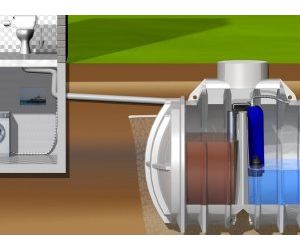

The principle of an AQUAMAX® small wastewater treatment plant is as simple as it is efficient: The wastewater flows from your house connection directly into the tank in your garden instead of - as usual - into the municipal sewer system. In this tank, the wastewater is now cleaned fully biologically, i.e. without the addition of chemical substances - by the way, far better than the legal requirements require. Once the clarification process has been completed, the treated wastewater is discharged into the nature.

Of course, the entire process is fully automatic - you don`t have to worry about anything. Even if you subsequently want to treat your wastewater for reuse, e.g. garden irrigation, the optional UV disinfection module AQUAMAX® BLUE (available for CLASSIC and BASIC) performs this task practically fully automatically.

Conclusion: With the AQUAMAX® an ideal wastewater treatment is very easy to realize!

No matter whether multi-chamber tanks or multi-tank plants, whether made of concrete or plastic, whether for new construction or retrofitting: The AQUAMAX® is the ideal small sewage treatment plant for every area of application - effective, innovative and sustainable. Up to 99% cleaning performance in only 8 hours!

The AQUAMAX® cleans incoming wastewater in 3 cycles daily, each lasting 8 hours. - First the waste water enters the primary treatment, then the 4-phase cycle follows.

1. Feeding phase

The water collected in the pre-treatment is fed into the treatment tank.

2. Treatment phase

During the 6-hour treatment phase, the wastewater is purified. Mixing, aeration and pause times alternate here.

3. Settlement phase

During the settlement phase, activated sludge settles at the bottom.

4. Clear water discharge phase

In the discharge phase, the clear water is pumped out of the system.

Frame made of recyclable plastic - robust, easy to maintain and very light. On this frame we give 10 years warranty!

With a patented flushing jet, the pump and pipe system are cleaned of residual sludge before the pumping process. This protects the environment and the existing percolation.

German Patent: DE 100 57 378

Thanks to a special valve newly developed by ATB, the submersible pump fulfils three tasks:

- Feeding process of the SBR chamber according to the suction principle (German Patent: DE 199 07 980)

- Sludge recirculation

- Clearwater discharge

Submerged aerator for fine-bubble aeration and gentle agitation in the treatment tank - specially developed for use in small sewage treatment plants.

First-class effluent values- Required effluent values are clearly met!

- General approval by the building authorities and safety tested by TÜV.

- Most sold SBR sewage treatment plant in Germany.

- The most comprehensive AQUAMAX® warranty package ever.

- 10 years on the frame, 36 months on all electrical and mechanical parts.

- *only available in Germany.

- Nationwide service network in Germany.

- Less electrical connections, less units, more safety!

- Even less energy consumption due to optimised process times, summer/winter operation and sludge removal operation!

- All units are safely located in the tank and not in the house.

- Special architecture makes AQUAMAX® BASIC particularly durable.

- Always up to date due to the AQUAMAX® modular system.

- Only 2 maintenance cycles per year, no wear-intensive blower.

Due to the patented ball technology, the AQUAMAX® BASIC requires one pump or one magnet valve less than conventional SBR systems. This means: less electrical connections, less risk of failure, more safety.

The principle: When a pump starts, water enters the feed pipe via a robust special valve. Depending on the pump duration, this alternates between filling / sludge discharge and pumping.

Short pumping: Initiates the filling phase of the SBR tank. Long pumping: The special ball closes the charging or filling pipe tightly after a few seconds; the water now reaches the clear water drain.

In this way, a large, heavy pump - i.e. an electrical unit - is completely replaced by a small ball.

EU-Patent: 04 010 152.9

The unique AQUAswitch® special level control integrated into the AQUAMAX® pipe system works practically maintenance-free, cleans itself and switches with millimetre accuracy.

German Patent: DE 10 2005 028 764.6