Workswell Smartis - Smart Thermal Imaging System

In the realm of industrial automation and control, the integration of thermal cameras has revolutionized how operations are monitored, maintained, and optimized. Unlike their visual spectrum counterparts, thermal cameras capture the infrared energy emitted by all objects, providing a heat map image that reveals temperature anomalies and patterns invisible to the naked eye. This unique capability opens up a myriad of applications across various sectors, driving efficiency, enhancing safety, and ensuring product quality.

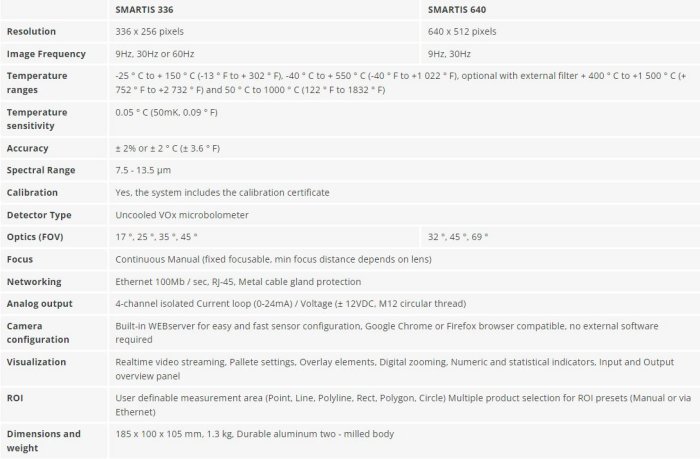

Workswell SMARTIS thermal camera can be operated and configured independently without the need for connection to a PC or a superior unit. The thermal camera is offered in resolutions of 160 x 128 px, 336 x 256 px a 640 x 512 px and an LWIR microbolometer of the spectral range of 7.5 – 13.5 μm has been used as an optical sensor.

The Workswell SMARTIS thermal camera is designed for process automation, machine vision, but also for continuous measurements of temperatures in metrological and research applications. The thermal camera has been designed for use in process automation in such a way that it can autonomously control a smaller process or its part or become a part of the control system. For this reason, it has been equipped with a TCP/IP interface (Ethernet 100Mb/sec, RJ-45) and also complemented with digital inputs and an analogue output (current loop 0-24 ma/12 V).

The measurement scope of the thermal camera ranges from -25 °C to 550 °C, optionally up to 1500 °C. Metrologic accuracy (±2% or ±2°C) and sensitivity (up to 50 mK, i.e. 0.05 °C) have stood as priorities in the thermal camera’s development.

The In-Built Webserver

The Workswell SMARTIS thermal camera contains an in-built webserver enabling a complete setting of the thermal camera, including measurement functions, inputs and outputs and image streaming options.

Communication Interface

- 4x current output (0-24 mA/12 V current loop)

- 7x digital output (with an open collector)

- 4x digital input/output for trigger

- Ethernet TCP/IP with a RJ-45 connector for communication with PLC, but also with the in-built webserver

- Automation

- Process control

- Machine vision

- Multi-pyrometric functions with Analog output

- Metrology and R&D for process control

- Fire-Safety applications

- Temperature measurement in food processes

- An in-built webserver for the setting of the thermal camera and visualisation of the data measured

- A TCP/IP interface for communication with a superior system

- digital inputs/outputs enabling triggering and alarm outputs

- Temperature measurement up to 1500 °C, calibrated within the full temperature scale

- A wide spectrum of measurement functions (temperature profile, measurement point, areas enabling minimum and maximum assessments etc.)

The Workswell SMARTIS thermal imager is designed for process automation, machine vision, as well as continuous temperature measurement in metrological and research applications . For use in process automation, the thermal imager is designed so that it can control a smaller process or part of it autonomously or become part of a control system. It is therefore equipped with a TCP / IP interface (Ethernet 100Mb / sec, RJ-45) but also with digital inputs and outputs and an analog output (current loop 0-24 mA / 12 V).

The measuring range of the thermal imager is from -25 ° C to 550 ° C, optionally up to 1500 ° C. During development, great emphasis was placed on metrological accuracy (± 2% or ± 2 ° C) and thermal camera sensitivity (up to 50 mK , ie 0.05 ° C)

The Workswell SMARTIS thermal imager includes a built-in web server that allows complete thermal imager setup, including measurement functions, inputs and outputs, and image streaming options.

An SDK is available to integrate the thermal imager into your devices. The SMARTIS Ethernet SDK is a set of commands designed to control a SMARTIS camera over an Ethernet connection without the need for a web browser. SMARTIS starts a TCP / IP server for control. An open server is similar to telnet and can be used with telnet terminal software.

- 4x current output (current loop 0-24 mA / 12 V)

- Power supply

- Ethernet TCP / IP with RJ-45 connector for communication with PLC but also with built-in web server

- 4x digital inputs / inputs for trigger

- 7x digital outputs (with open collector)