- Home

- Companies

- SnowPure Water Technologies

- Products

- SnowPure Electropure - Model EXL-650 - ...

SnowPure Electropure - Model EXL-650 -Electrodeionization (EDI) Modules

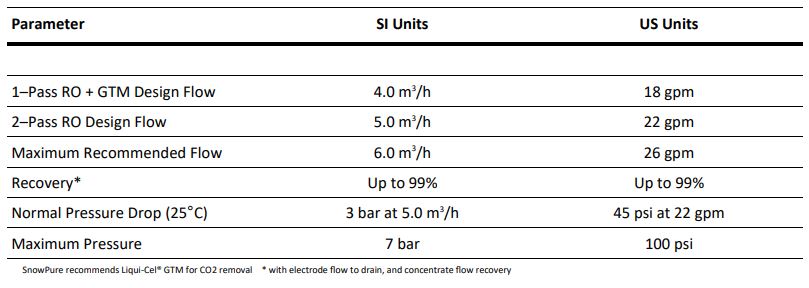

ELECTROPURE EXL-650 EDI modules are designed to be the highest rejection EDI modules on the market. EXL is configured to easily build ultrapure water systems with the well -known benefits of Electropure EDI technology. The EXL-650 achieves high quality even with 1-Pass RO, saving you money.

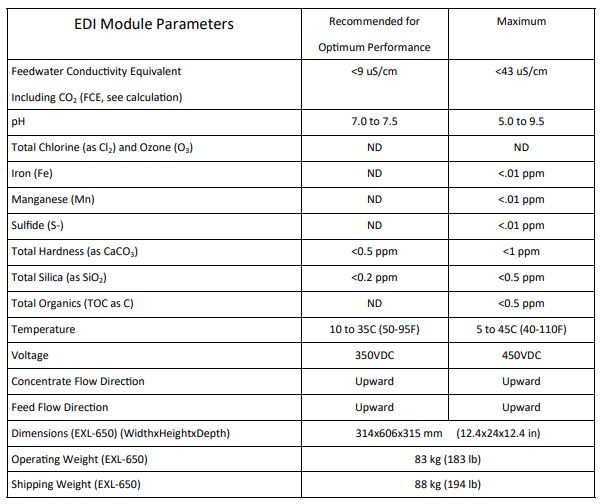

ELECTROPURE EXL-650 modules have next-generation innovative technology inside. The 650 series is designed to handle higher FCE, Feed Conductivity Equivalent. This means that the EXL-650 will perform very well at higher TDS and higher co2 and Si02 loading. As always EXL includes Electropure`s patented Excellion membranes, "never-leak" permanent O-ring seals, unique non-scaling electrode system, efficient thin-cell technology, and connections using +GF+ unions.

Electropure EDI thin-concentrate technology effectively eliminates scaling. And with Electropure ETDI technology`s excellent mass-transfer design, you don`t need salt injection, you don`t need feed-and-bleed systems, and you don t need the IONPURE "all-filled" design.

- No concentrate recirculation or brine injection

- Thin-Cell efficient technology

- Thin-Concentrate non-scaling technology

- Unique non-scaling electrode system

- Patented Excellion™ membranes

- Electropure™ Electrodeionization technology was born in 1977, before lonpure

- SnowPure is privately held

- SnowPure is your partner, not a competitor

- High quality Electropure™ EDI training and OEM support

- Continuous Process-no upsets

- Operating cost is minimized

- No hazardous waste, no associated costs and risks

- No regeneration acid or caustic

- Flexible—easy to expand a modular EDI system

- Reliable—no recirculation system components to fail

- SnowPure believes strongly in training—this helps ensure field success with Electropure™ Electrodeionization systems.

- SnowPure assists new OEM customers through their system design phase, both during the OEM training and during the design process. Support includes reviews of P&l diagrams and feedwater requirements.

- Combined with ongoing Technical Service, we help ensure success.