- Home

- Companies

- SOLTEC Novomoskovsky Mechanical Plant ...

- Products

- SOLTEC - Model BM Series - Automated ...

SOLTEC - Model BM Series -Automated Dosing Pumps

BM dosing pumps are applied on the manufactures where the technological processes demand accurate dosage of viscous heterogeneous components with interval of no more than 0.1 %, taking into account the outlet pressure. BM dosing pumps can be automated and allow the installation of wide range of additional options, such as charging neck, supporting screw conveyer, heating system of current part etc. For using in various processes BM pumps units can be of different assembly: industrial, hygienic chemical and explosion-proof.

SOLTEC Single screw eccentric progressing cavity pumps belong to the class of volumetric ones that is a certain amount of pumping fluid corresponds to each revolution pump rotor, at the same time the regulation of pump unit revolutions allows the thin dosing of viscous heterogeneous fluids under the constant pressure at the outlet.

- productive capacity from 0.01 to 1 m3/h

- pressure from 4 to 24 bar

- various options

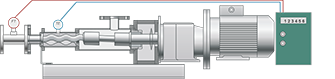

The dosing is carried out by the regulation of shaft revolutions due to frequency converter or a variator. The interval of dosing is no more than 0.1 %.

BM Progressing cavity pumps allow the accurate dosing of the pumping fluids with the differential pressure up to 24 bar, at the same time the pressure remains constant at any productive capacity of the pump unit.

For the automation process of dosing can be installed additional options: mass sensors, flow sensors, flow transducers, sensors of “dry running”, revolution counters of driving shaft etc.