- Home

- Companies

- A&A Coatings

- Products

- A&A Coatings - Spray and Fuse Nickel ...

A&A Coatings - Spray and Fuse Nickel Chrome Boron Material

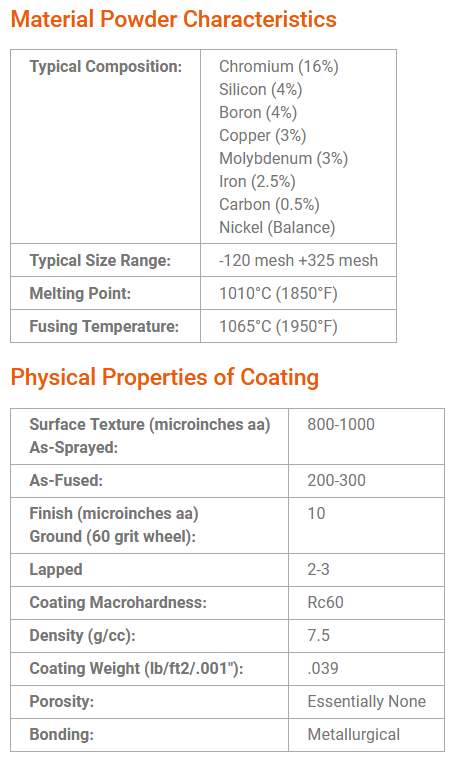

A&A Coatings Nickel-Chrome-Boron material is one of several self-fluxing alloys that is designed to be “fused”, or remelted in a normal atmosphere, after being sprayed. They then coalesce into a dense, essentially pore-free coating.

Nickel-Chrome-Boron produces coatings which resist wear by abrasive grains, hard surfaces, particle erosion, fretting, and cavitation. It is useful for nearly all hard-facing applications, especially on irregular shapes, and where heavy coatings are required.Coatings up to 1/8″ (3 mm) or more in thickness may be fused without difficulty.

Of all of the A&A self-fluxing alloys, Nickel-Chrome-Boron is generally the most resistant to corrosion.

Fusing

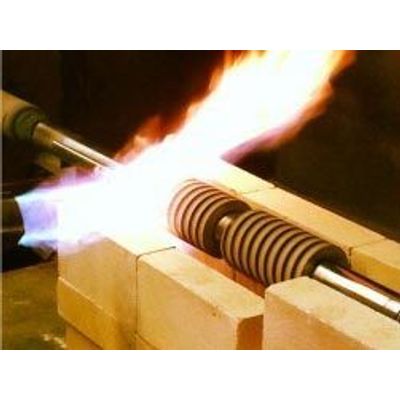

Fusing Torch is adjusted to produce a soft, slightly reducing flame. Work piece is preheated the evenly from a distance of about 4-5″, moving the flame back and forth over the surface, to a temperature of 315-540ºC (600- 1000ºF).

After preheating, the torch nozzle is moved to a distance of about 1.5″ from the work piece, about 1″ in from the edge of the coating, and oscillated slightly as the fusing point is reached. The coating shows a glassy “shine” when it fuses.

When fusing is finished, the work piece is cooled slowly by burying it in vermiculite.Fast cooling may crack the coating. Alternatively, fusing can be done in a furnace or by induction.

Finishing

A&A Coatings fused Nickel-Chrome-Boron should be finish ground to size.