- Home

- Companies

- Esmesan Spraying Machines

- Products

- Esdoru Turbo - Model 600LT - Spraying ...

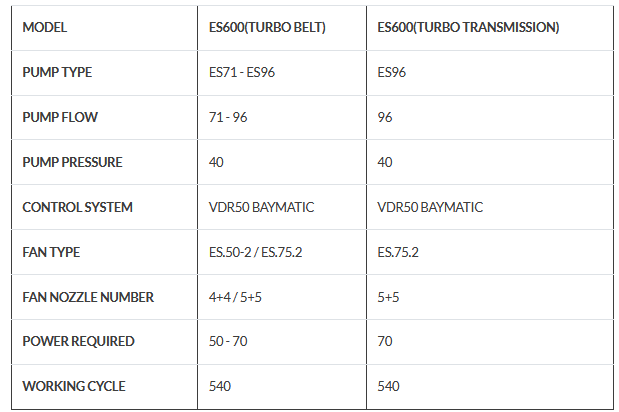

Esdoru Turbo - Model 600LT -Spraying Machine

With the separator on the fan, it is taken to idle when desired, and the rotation of the fan propeller is stopped. The air flow rate can be precisely controlled by adjusting the direction of the moving blade of the fan. By adjusting the angle and direction of the nozzles on the fan or by changing the plates, the shot distance and the amount of drug can be adjusted. By using the distributor valves on the regulator, medication can be delivered to the right, left or both directions.

By connecting to the tractor from 3 suspension points, the power is transferred to the turbo fan by belt-pulley or gearbox. The pressure required for spraying is provided by pumps produced by Esmesan with a hydraulic membrane. A fiberglass or polyethylene tank is used as a spraying tank. With the separator on the fan, the rotation of the propellers is stopped by taking it to idle at any time. The air flow rate is controlled by adjusting the direction of the moving propeller of the fan. By adjusting the angle (spray) and direction of the nozzles on the fan or by changing the plates, the shot distance and the amount of drug dispensed can be adjusted. By using the distributor valves on the regulator, medicine can be thrown to the right, left or both directions. With the separator on the fan, it is taken to idle when desired, and the rotation of the fan propeller is stopped. The air flow rate can be precisely controlled by adjusting the direction of the moving blade of the fan. By adjusting the angle and direction of the nozzles on the fan or by changing the plates, the shot distance and the amount of drug can be adjusted. By using the distributor valves on the regulator, medication can be delivered to the right, left or both directions.