- Home

- Companies

- Dinesh Tube ( India)

- Products

- Dinesh - Model SMO 254 - Stainless ...

Dinesh - Model SMO 254 -Stainless Steel Forged Fittings

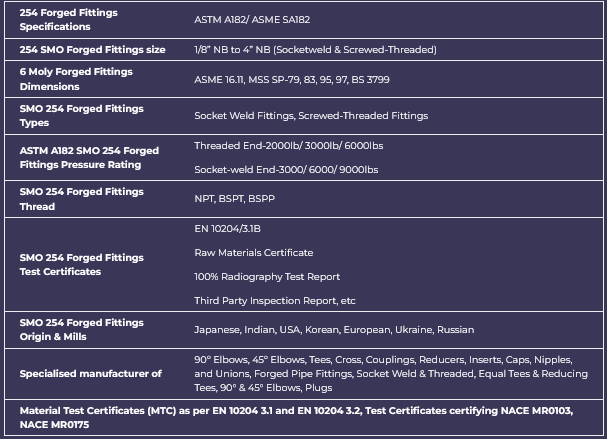

SMO 254 Forged Fittings,ANSI/ASME B16.11, BS3799, ASTM A403 SMO 254 Forged Pipe Fittings Manufacturer, Exporter & Suppliers,SMO 254 UNS S31254 Threaded Forged Pipe Fittings, Socket weld Forged Pipe Fittings, Forged Elbow Suppliers in India. Stockist of 254 SMO Forged Elbow, SMO UNS S31254 Forged Pipe Fittings, SMO 254 Forged Fittings, UNS S31254 Socket weld Fittings, SMO 254 / 6 Mo Threaded Fittings Supplier, SMO 254 Forged Screwed Fittings Exporter, SMO 254 Threaded Plug, SMO 254 Socket Weld Cap, ASME SA182M SMO 254 Class 6000 Fittings, SMO 254 / 6 Mo Equal Tee, Manufacturer Of ASTM A182 SMO 254 Bushing, SMO 254 ASTM A182 Cross, SMO 254 Full Couplings,Elbow, Werkstoff No 1.4547 SMO High Pressure Forged Fittings, SMO 6Mo Forged 90 Deg Threaded Elbow

The Steel Exporter manufactures and produces steel SMO 254 Forged Fittings and various mountings for forged fittings. Globally, it exports its unique range of products. We continue to produce unmatched steel products using state-of-the-art technology, attracting a large number of customers from prestigious industries through our innovative and technical workforce.

As a result of our commitment to sustainability in design and construction, our company has received numerous accolades and certifications. Our products are known not only for their good design and advanced technology, but also for their quality. By designing our products according to industrial demands and calibrating them according to international standards, we have been able to sustain market competition.

Also available are Socket Weld and Threaded SMO 254 Forged Fittings. These SMO 254 Forged Fittings provided by us are capable of withstanding corrosion, extreme temperature conditions and chemical reactions. ASME A403 SMO 254/6Mo Forged Fittings which are added with Molybdenum, giving it superior powers to withstand corrosion in halide containing environments, like seawater, pulp and bleach mills, brackish waters, etc.These SMO 254 Forged Fittings are available in various specification and thickness as per clients requirements.

Once the SMO fitting is assembled, it is sent to a variety of locations. The SMO fitting is sent to a variety of locations after it has finished. We perform various tests under the guidance of our expert team. Third-party inspection is also permitted if requested by our customers. To prevent damage during shipment, we also use standard packing methods. Most of the time, this fitting is packaged in bundles. We offer this fitting at an affordable price. Now is the time to get this fitting from us.

SMO 254 Forged Fittings resist the corrosion which happens when other products get exposed to hydrochloric and sulfuric acids. It is suitable to use in high-temperature applications and in a halide containing environment. SMO 254 Forged Fittings is most commonly used in petroleum production, chemical processing industry, food processing industry, condensers, aerospace, marine industry, nuclear plant, pharmaceutical, power plant, etc.

The Steel Exporter manufactures zero error SMO 254 Forged Fittings using the latest modern technology. Additionally, we maintain our technology by providing regular time-to-time service to produce Forged Fittings without experiencing any problems. For excellent product stability, we use standard quality grade materials.

We procure raw materials from reliable vendors and make use of technology quickly with the help of expert teams. Under the supervision of experts, SMO 254 Forged Fittings are manufactured according to a standard procedure.

Documents:

- Certificate of Origin legalised/attested by Chamber of Commerce or Embassy

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight and gross weight, Marks and Numbers

- Fumigation Certificates

- Letter of Guarantee

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

- Raw Material Test Reports

- Heat Treatment Charts

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- MATERIAL TRACEABILITY RECORDS

- Quality Assurance Plan (QAP)

- NABL approved Laboratory Test Reports

Testings (Destructive, Non Destructive):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulphide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- UltraSonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

Packing:

- We understand the importance of packaging especially in case of international shipments as the consignment has to go through a number of channels to reach the final destination, thus we take proper care of packing.

- We pack our goods in various ways depending on the products. The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking:

- All our products will have complete marking details which are co-related to the test certificates we supply.

- In case of orders for cut pieces of Pipes, Sheets or Round Bars, the marking is transferred from the product from which it is cut. In such cases we provide Letter confirming the marking transfer and a picture of the product from which it is cut.

Delivery Time:

- If the items are available in stock, we take 2 days from the date of receipt of advance payment to clear the shipment and send it to port.

- And in-case the items are not available in stock, the time taken for manufacturing depends on the size, quantity and grade.

- However we can claim the fact that we can compete with anyone in India on Delivery time and most of the time our production time is the least.

- We have tied up with strong logistic partners in India which can undertake any type of shipping activities and make sure that there is no delay in shipment.

Price Basis:

- We can offer any of the following price bases depending on your requirement:

- Ex-works

- FOB Nhava Sheva

- CFR, CIF, CPT your destination port

- Door to Door Delivery Duty Paid as well as Duty Unpaid

Inspection:

- We welcome stage wise inspection, final stage inspection from any of your representative or third party inspection agencies.

- We regularly have inspections ongoing at our premises from internationally acclaimed Inspection Agencies such as TUV, Lloyds, BVIS, SGS, DNV etc.

Additional Information:

- We offer pipes on a cut to size basis also, if your project demands pipes of particular lengths, you can feel free to contact us.

- We have a good amount of stock to fulfil your urgent requirements, however if a certain item is not in stock, please don’t hesitate as we also process small size/quantity orders, we hardly have minimum order quantity obligations.

- We also offer cut pieces for plates, sheets. We can cut them as per your sizes. We can also cut circles and rings as per your dimensions. The cutting is done through water-jet and laser and plasma technologies.

- Forged Fittings for Chemical

- Food, Beverage

- Oil and Gas

- Petroleum Refining

- Power Generation

- Thermal, Nuclear and Solar Power Plants

- Petrochemicals and Refineries

- Marine & Dredging

- Dairy Industry