- Home

- Companies

- Piyush Steel

- Products

- Piyush - Model 304H - Stainless Steel ...

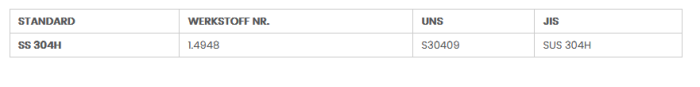

Piyush - Model 304H -Stainless Steel Pipes

SS UNS S30409 Pipes, ASTM A312 TP304H SS Welded Pipes, SS 1.4948 Seamless Pipes, Stainless Steel 304H Seamless Pipe, Stainless Steel 304H Pipes Supplier in Mumbai, India.

About 304H pipes-

Stainless Steel S30409 Seamless Pipe are basically austenitic stainless steel that is well tested and is securely verified by the quality controller so as to make sure a high performance, best strength, and categorical quality product. The pipes can be easily grouped in appropriate thickness, surface finish, length, and width. The alloy pipes can also be served in cut-to-length size and it can be machined as well as fabricated so that it correctly meets the requirement of the client. It is basically a modified version of 304 with more controlled carbon content in the range of approx. 0.04-0.10 for desired strength at a particular temperature such as 800 deg F.

Stainless steel pipe properties-

The stainless steel 304H pipe possesses high corrosion resistance and it contains an appropriate amount of chromium. The chromium is responsible for forming a self-healing layer of oxide that gives stainless steel pipe their corrosion resistance properties. It also offers resistance at cryogenic temperatures. Cryogenic resistance can be easily measured by toughness or ductility at zero temperature. It has a high tensile strength at ambient temperature. It has maintained excellent toughness. The strength of the pipe is achieved through cold working and thus fabrication component receives appropriate strength. It can recollect the strength at some eminent temperature. The high chromium content helps to resist scaling at peak temperatures. The pipe offers great ductility and work hardening allow the formation of stainless steel using severe processes like deep drawing. In comparison to mild steel, it has strength double. Other known properties of SS 1.4948 Welded Pipe are heat resistant qualities, great creep strength, and high tensile yielding strength. In contrast, it offers high weldability, corrosion as well as oxidation resistance so that it performs well. It has a typical application such as commercial and home application including container and tank for a variety of solid and liquid.

Testing-

Various test got performed on stainless steel pipes after its manufacturing and are follows-

- Mechanical testing

- Chemical analysis

- Flattening test

- Pitting resistance test

- Macro and micro test

- Positive material identification test

- Flaring test

- Intergranular corrosion test or IGC test

The product is certified too, raw material certificate, EN 10204/3.1B, and third-party inspection report are some of them.

Documentation-

After testing comes to the documentation. Documentation plays an essential part because it is proof that the product is well tested and the quality is maintained. It also tells about the product credibility and ease of work. They are as follows-

- Certificate of origin

- Packing list

- Commercial invoice

- Quality assurance plan

- Heat treatment charts

- Material traceability records

- Fumigation certificates

- Material test certificate

- Guarantee letter

- NABL approved test reports

- Form A of Generalized system of preferences

- Welding procedure specification

SS 304H Pipe Packaging-

The stainless steel 304H pipes can be packed using polypropylene sheets, flat steel bands, wooden cases, wooden pallets, and wooden boxes. It can be shipped in bundles so as to prevent it from rusting and damages. The product can be marked or labeled so that it doesn’t get lost. With capped end pipe of around 3,” OD is supplied in bundles.

Markings On The Stainless Steel 304H Pipes

The full identification of the pipe should be continuously marked down its whole length, including :

- Nominal Pipe Size (Nominal Bore)

- Schedule (Wall Thickness)

- Specification

- Grade

- Method of Manufacture (Seamless or Welded)

- Heat Number

- Manufacturer’s Name or Symbol

- Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

- Dimension Standard : ANSI B36.19M, ANSI B36.10

- Outside Diameter : 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock

- Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

- Type : Seamless / ERW / Welded / Fabricated Pipes

- Form : Round, Square, Rectangular, Oval, Hydraulic Etc

- Length : Single Random, Double Random & Required Length

- End : Plain End, Beveled End, Treaded

- End Protection : Plastic Caps

- Outside Finish : 2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

- Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

- Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

- Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

- Specials : Sizes and Specifications other than above can be manufactured on request

- Petrochemical Industry

- Chemical Industry

- Oil and Gas Industry

- Pulp & Paper Indusry

- Power Plant Industry

- Food Processing Industry

- Pharmaceuticals Industry

- Energy Industry

- Aerospace Industry