- Home

- Companies

- TOC Systems, Inc.

- Products

- StarTOC - Model Series SA 900 - ...

StarTOC - Model Series SA 900 -Semi-Automatic TOC Analyzer for Solids/Liquids Analyzer

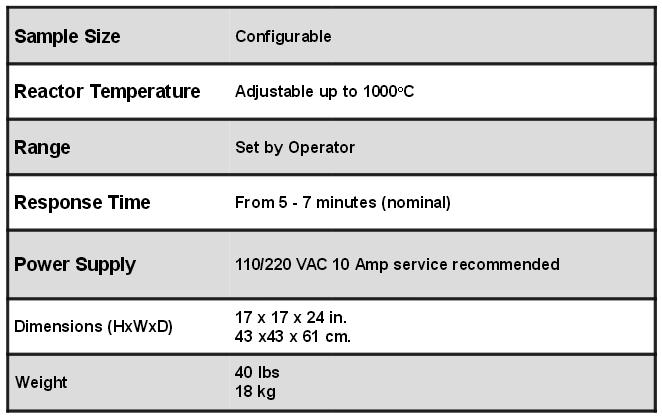

Series SA 900 provides a platform, which may be configured for a variety of applications, combustion temperatures, catalyst/non-catalyst choices and different Regulatory and Standard Methods. It is an ideal tool to support current development programs, as well as providing capability for any future mandated requirements.

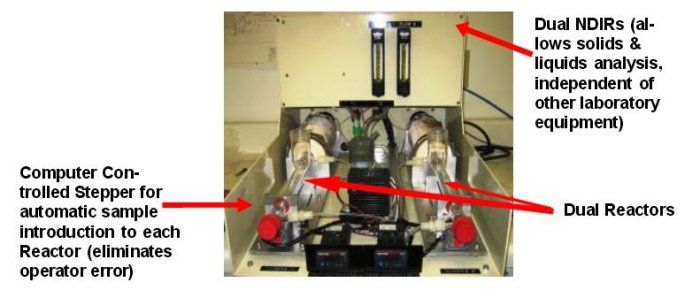

- Complete with Dual NDIRs

- Dual Reactors

- Automatic Boat Injection

- Scale with Computer Interface

- TOC - Direct

- TOC - Differential

- 5 grams Sample Size

Description:

StarTOC Solids/Liquid Analyzer provides a platform, which may be configured for a variety of applications, combustion temperatures, catalyst/non-catalyst choices and different Regu- latory and Standard Methods. It is an ideal tool to support current development programs, as well as providing capability for any future mandated requirements

Applications (partial)

- Solids, Slurry, Particulated Liquids Cleaning Validation (Swab Method)

- Combustors/Hazardous Waste Emissions

- Incinerator Residue

- Groundwater/Soil Contamination

- Agricultural Studies/Planning

Configurations

The hardware provides the operator with a high degree of flexibility to improvise the configuration parameters, such as temperatures, reactor catalyst choices or a non-catalytic reaction. The following two (2) methods are currently preferred.

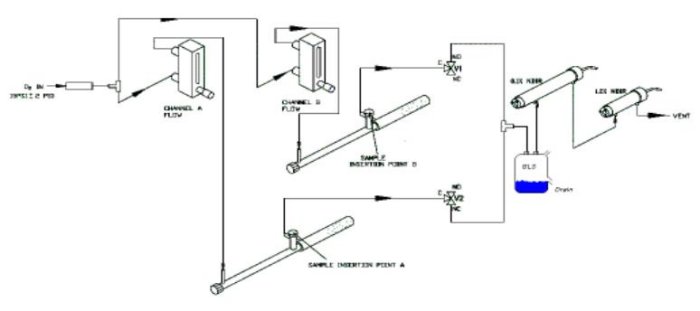

TOC - Direct Mode

This method uses a single, dual-zone heated Reactor. The operator acidifies the sample, which is initially introduced to the 250°C heat zone, where all TIC is vaporized to C02 and measured as TIC. After TIC vaporization, the sample is automatically placed in the high temperature heat zone, where the TIC-Free sample is oxidized to C02 and reported as TOC.

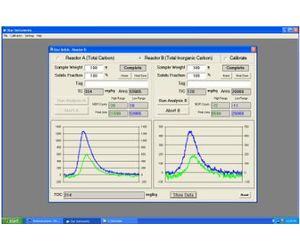

TOC Differential Mode

This method uses one Reactor, set to a high temperature, to combust all the carbon in the sample, to be reported as TC (Total Carbon). Another portion of the same sample is acidified and introduced to the Second Reactor, set to 250°C and is reported as TIC. The computer mathematically subtracts the TIC analysis from the TC analysis to deriveTOC:

TOC = TC - TIC

1. Weigh Sample (Sample Weight Automatically Entered)

2. Enter Solids Fraction (Operator)

3. Enter Sample Tag (Operator)

4. Position Crucible on injector

5. Sample Automatically Injected

6. Automatic Analysis

1. Dispense Specified Amount of Sample by Syringe

2. Perform Same Functions as with Solids Analysis (above)