Statiflo - Model NR -Non-Ragging Inline Static Mixer

The Statiflo Non-Ragging (NR) Pipe Mixer – also called a Non-Blocking or Non-Clogging Static Mixer – is a high performance Static Mixer which has been specifically designed for sludge mixing or wastewater applications with high fibre content. The mixer’s free flow design gives excellent resistant to blocking, clogging and ragging meaning downtime is drastically reduced compare to the use of a regular-style static mixer or other mixing device. Combining the lack of ragging with the high mixing performance and consistent mixture quality achieved by the Statiflo NR Pipe Mixer, it is clearthat this product is a must for your wastewater application.

Full testing has been carried out on the Non-Ragging Inline Static Mixer for mixture quality and pressure drop. Along with this, onsite trials have been conducted to prove the mixer’s resistance to blocking, clogging and ragging.

In full-scale trials with a major UK water utility the Statiflo NR Pipe Mixer outperformed all competitor’s designs including a static mixer, an orifice plate and sludge valves.

These pictures and graphs illustrate the superior performance of the Statiflo NR Mixer compared with a competitor’s mixer. The graph shows the typical effects of ragging with increasing headloss and reduced flow until the competitor’s mixer ceased to operate in less than four hours.

The Statiflo NR Mixer is proven to be suitable for the following applications:

- Sludge blending

- Sludge thickening

- Ferric sulphate and ferric chloride dosing for phosphorous removal

- Coagulant / polymer dosing

- Chemical dosing of sewage

- Industrial wastewater treatment with fibres including paperstock

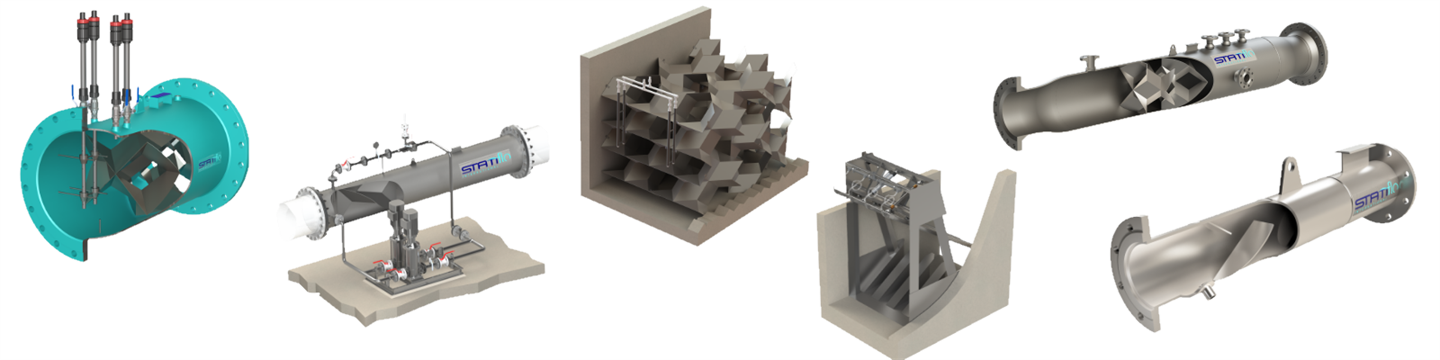

Market-leading mixing element designs

Supplied with fixed Non-Ragging (NR) elements with a free flow design which gives excellent resistance to blocking and ragging whilst still providing high mixing performance and consistent mixture qualities.

Available for almost all pipe sizes

Diameters from as small as DN50 (2″) with no theoretical upper limit.

Superior mixture qualities achievable

Designed to achieve a Coefficient of Variation (CoV) of 0.05 or less – meaning you can take a representative sample shortly after the mixer to improve process control.

Accessories to complement

Available with optional integral injection/sample connections.

Materials to suit your requirements

Typically supplied in uPVC, stainless steel or epoxy coated carbon steel. Other commercially available metallic materials available on request.