Statox - Model Statox 505: SIL 2 Compliant -Toxic Gas Detector

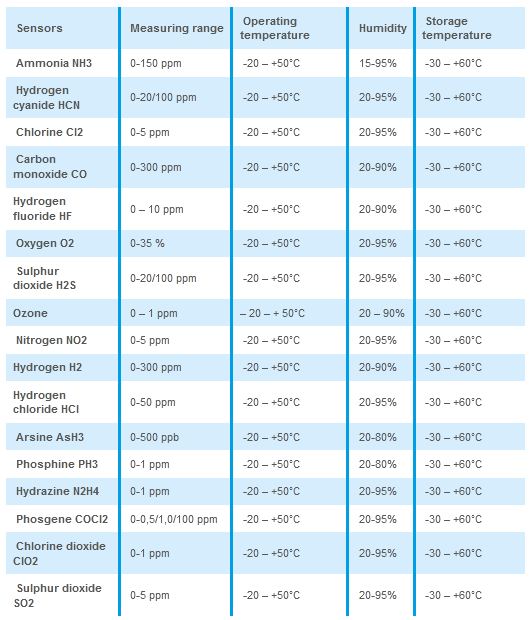

You always know what is going on in your plant: Gas detection system Statox 505 compliant to SIL 2 Standard. Intelligent Gas Sensors for AsH3, Cl2, ClO2, CO, COCl2, H2, H2S, HCl, HCN, HF, N2H4, NH3, NO2, O2, O3, PH3 and SO2. The Statox 505 new 4 – 20 mA Transmitter for toxic gases and oxygen features everything that a new gas detection instrument of the latest generation needs: State of the Art components (hardware and software), smart sensor technology, “heartbeat” sensor control and complete system diagnostics on board.

In process monitoring, the status of plant components in case of a failure is becoming more and more a critical issue. The standards DIN EN 61508 as well as the product standard DIN EN 50402 are powerful tools to calculate the probability of a failure on demand. The Statox 505 complies with all of the requirements of these standards. It obtained the safety integrity level SIL 2. This provides a reliable database for the user to calculate the safety standard of his plant. If the Statox 505 is operated as a SIL 2 component, a so called “proof test” in certain time intervals is mandatory.

All important parameters such as sensor „heartbeat“, signal output, calibration, zero, sensitivity, temperature, sensor memory, amplifier, CPU, power supply etc. are continuously monitored for proper function. In case of a failure, an alarm will be triggered. Thus the system cannot fail without the error being noticed. A green LED signalizes the system status. The display and the controls are located at the inside of the housing – well protected from the elements.

The sensors of the Statox 505 are plug and play technology. Each sensor has a F-RAM on board which communicates all relevant parameters to the sensor head: Gas, measuring range, last calibration, ex works calibration, response time etc.

The sensors can easily be calibrated in the shop. For the user this means that he never ever will have to do calibration work in the harsh elements (wind, rain, cold, heat). No more lugging heavy test equipment and gas cylinders into the field. All the user has to do in the field, is plug the sensor back in. To do that, you don`t even need a tool! While the sensor is getting calibrated in the shop, the sensor cartridge stays in place and protects the sensor head from dust and rain.

The Statox 505 comes with a mounting plate for either wall – or pipe mounting. No need to open the sensor head for plant installation.

- Sensor head: Statox 505 Type 5375…

- Display: 8 – digits, 14 segments

- Output: – 4-20 mA, max. load 700 Ohm, service mode: 0 or 2 mA, System fail 0 or 2 mA, overrange 22 mA

- Protection class: IP 65

- Approval: II 2 G EEx ib IIC T4

- Dimensions (HxBxT) without mounting plate: 200 x 120 x 90 mm

- Pressure: 900 – 1100 hPa

- Operation- and storage temperature: – 30 °C to + 60°C

- Power supply: 12 – 28 V DC max. 22 mA

- Weight: 0,75 kg

- Housing: Chromium plated ABS, stainless steel, mounting plate stainless steel

- Operation voltage Ui: max. 28 V DC

- Operation current: max. 93 mA

- Internal capacity Ci: neglectible

- Internal inductivity Li: neglectible

- EMC: EN 50270

- Functional safety: SIL 2 according to EN 50402