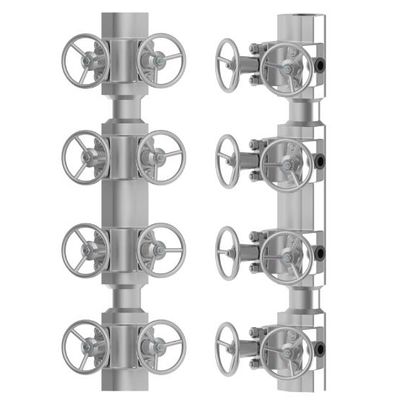

CV/CC -N - Model CV/CC -N -Steam Distribution / Condensate Collection Manifold

In large steam using industries, long distribution lines for steam and condensate service provide a constant source of maintenance hazards and energy wastage through numerous leakages. BiTherm steam and condensate manifolds are designed to solve such long standing problems (vertical installation). Fabricated headers to supply steam and collect condensate from cause a constant source of leakage. More over this also spoil the aesthetics of a well designed plant. What with continuous monetary losses due to energy wastage.

Body design conditions

ANSI Class 300 designed for a maximum cold hydraulic test pressure of 76 barg.

Size and pipe connections

Manifolds are avaible with 4, 8 or 12 connections. End connections.flanged to ANSI class 150 or 300, socket toANSIB16.11 class 3000.

The steam main / condensate return connection is 1 1/2". The tracer line and drain connections are avaible as 1/2" and 3/4".

BiTherm steam and condensate manifolds are made from forged steel to suit various operating conditions. These are available in configurations of 4, 8 or 12 ways.

Integral piston valves of seatless design will ensure that leakages across seat are eliminated totally.

Forged design minimizes the welding requirements making it much easier to operate and maintain. Space-saving design is for vertical installation. A simple arrangement of threaded M16 connection at the back provides a better way of attaching these manifolds to structural supports.