- Home

- Companies

- QToploader International BV

- Products

- Storage and Dosing System

Storage and Dosing System

Advantages: minimal energy consumption. High reliability. Light construction. Fully emptying of silo. Bridging of material no problem. All moving parts on top of material. Easy access for servicing. Minimal maintanance. No in-ground structures. High capacities. Very cost-effective investment. Full redundancy.

woodchip and bark

sawdust and shredded wood

compost and peat

by-products

chicken litter

fertiliser

kernels

food waste

RDF-SRF

dry recyclables

recycled plastics

sludges

grain and pellets

coal and incinerator slags

fibers

glass and gypsum

metals

heat generation

power generation

combined heat and power

composting

digesting

drying

cooling

shredding

screening

dosing

mixing

conditioning

recycling

loading systems

production processes

intermediate storages

biogas production

biomass boiler systems

energy from waste

pyrolysis

hydrolysis

farming

greenhouses

food recycling

metal recycling

tyre recycling

stevadoring

chemical industry

cement industry

papermills

car recycling

QTOP

standard for average applications

High Performance for high storage and dosing capacities

Heavy Duty for difficult applications

containerised system for light applications, including walls

for light applications

and limited capacities

double storage

for optimal use of building

for controlled mixing and conditioning

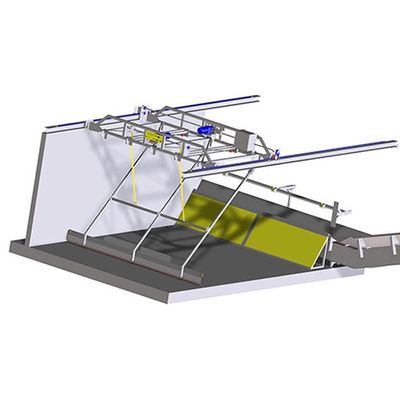

The QToploader consists of a trolley that moves horizontally with an attached scraper construction that moves vertically up and down following the top of the product layer in the storage area.

The storage area is filled by an overhead conveying system or by a reversing trailer emptying directly into the storage area. During the filling of the storage bay by a trailer the QToploader stays in parking position for safety reasons. During filling by an overhead conveyor, the QToploader can continue dosing.

After filling, the QToploader trolley moves to the back of the storage area and starts scraping the product to the front of the storage area near the discharge conveying system. It starts to stack the product at the front end of the storage bay. It continues stacking until there is no more product to stack.

After stacking, the QToploader switches to dosing mode. It brings the product onto the discharge conveying system, which is placed at 90 degrees to the storage area. If the product needs to be dosed during stacking, this dosing has priority.

After discharging, the scraper arm is pulled up and the trolley moves backwards to the beginning of the remaining stockpile of material. There the scraper goes down again and the full cyclus starts again. When there is no demand for product, the QToploader stays idle in standby, ready for dosing.

Dimensions

width: 2-8 meters

length: up to 100 meters

product layer: 1-5 meters

storage volume: up to 1200 m3 per QToploader

special dimensions on request

Motordrives

traverse movement: 1.1-15 kW

hoisting scraper: 0.55-3.0 kW

brake systems

frequency controlled (VSD)

Components

HEB rails with wall supports

chains

trolley

lifting arm with scraper

ramp at discharge side

PLC control unit with touch screen

full cabling

Control system

fully automatic dosing and stacking

visual presentation of actual stock level

programmable re-ordering set point

programmable access times to storage area

first-in first-out dosing possible

remote control

service mode

data logging

VPN connection for remote support

operational statistics

Finish

galvanised

stainless steel

turnkey installation

start-up and commissioning

QToploader options

multiple QToploaders

special dimensions

storage in basement

tilting scraper

scraper at door for better use of silo

rubber scraper for wet products

earthquake resistant version

special scraper design

multiple dosing capacities

access control systems

Transport

standard curtainsided trailer

40’ container

export documents

Loading of storage bay

by reversing trailer

by overhead conveyor

Dosing

full scraper dosing for high capacities

partial scraper dosing for low capacities

controlled continuous dosing

surge dosing for very high dosing capacity

combination with (existing) sliding floor

combination with (existing) walking floor

combination with (existing) rotating scraper

Discharge systems

belt conveyors

screw conveyors

chain conveyors