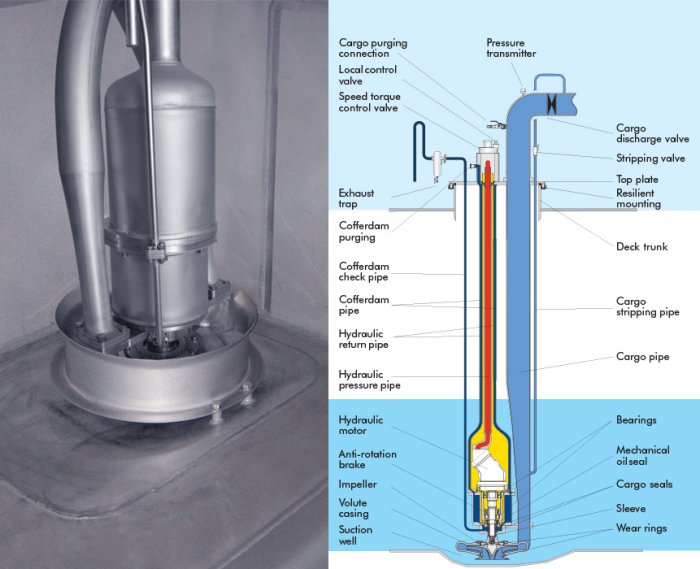

Framo - Submerged Cargo Pump

More than a half-century after we introduced it, the Framo submerged cargo pump is still a unique solution – used by nearly all vessels in the world that handle liquid cargo. It has the ability to pump any type of liquid cargo, no matter how sensitive or viscous. The Framo cargo pump is a vertical single-stage centrifugal pump powered by a hydraulic motor for safe and efficient operation. All of our cargo pumps are made in stainless steel and designed with a smooth and easy-to-clean surface featuring a limited number of flanges for a superior ability to pump any liquid.

- Vertical single stages, single suction impeller, axially balance

- Robust hydraulic drive with short and stiff drive shaft

- Fail-safe design; lubrication and cooling of pump by the hydraulic driving oil medium.

- Pump material stenless steel

- Concentric hydraulic pipes for maximum safety

- Cofferdam, ventilated to atmosphere, protecting the entire pump

- Mechincal seal against hydraulic oil

- Double lip seal against cargo, only exposed to static pressure

- Anti-rotation brake; loading through pump

- Smooth pump exterior; self draining and easy to clean

The Framo cargo pump is easy to operate. The hydraulic drive provides for a remote and local stepless capacity control through the Speed Torque Control (StC) valve on the pump`s top plate. The cargo pump can pump anything liquid, regardless of specific weight or viscosity.

It is impossible to overload or to overspeed the pump. The STC valve automatically regulates hydraulic oil pressure and flow to the hydraulic motor according to the give discharge situation.

The pump design allows operation with a minimum of liquid in the tank which saves time spent for drainage and tank cleaning. The Framo cargo pump has a built-in efficient stripping system.

Seal monitoring is performed from the cargo pump top plate by purging the cofferdam.

Replacement of wear and tear parts is easily done from inside of the tank without interfering with the hydraulic section.