Omnisens SA

Omnisens - Model Subsea -Subsea Asset Monitoring System

FromOmnisens SA

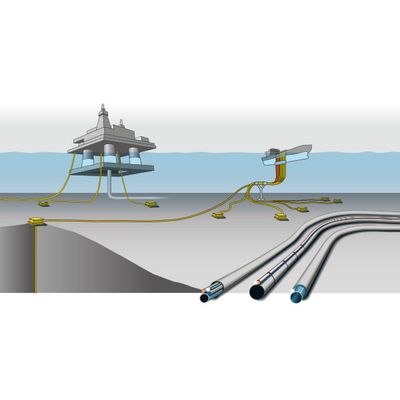

Monitoring with distributed fiber optic sensing provides continuous real time information about temperature and/or strain events along the length of the asset, helping to detect possible failures at the earliest stage, giving the operator time to take action. This monitoring can be used alone or included in an asset integrity management program, alongside in-line inspections and/or as a feedback loop for models.

Most popular related searches

distributed fiber optic sensing

asset integrity management

inline inspection

fiber optic sensing

asset monitoring system

leak detection

distributed optical sensing

flow detection

asset management program

optical sensing

- Control and performance monitoring (topside) of electrically heated flowlines (Direct Electrical Heating (DEH), trace heated pipe in pipe).

- Flow assurance: detecting and locating cold spots which may indicate the requirement for more heating, injection or other flow assurance technique.

- Automatic, real-time fiber optic break detection, indicating asset damage.

- Leak detection: for example, water ingress.

- Flow assurance: detecting and locating cold spots which may indicate the requirement for more wax inhibitor injection or other flow assurance technique.

- Early stage leak detection whether water or hydraulic fluid or hydrocarbon ingress or egress.

- Condition monitoring on power umbilicals

- Performance and fitness for purpose evaluation (power umbilicals) by comparing temperature response to different electrical loads.

- Condition monitoring:

- Temperature monitoring along the length of the asset, detecting hot or cold spots

- Fatigue and elongation detection and location.