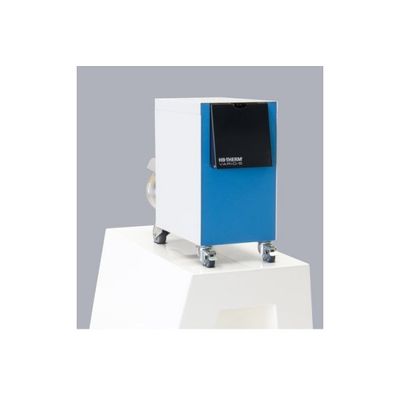

HB-Therm - Model Vario-5 -Switching Unit for Variothermal Temperature Control

Special challenges in injection molding processing can no longer be mastered with conventional temperature control. The solution is variothermal temperature control: high temperature during injection, cold temperature in the cooling phase. Together with two Thermo-5 temperature control units, the Vario-5 switching unit forms a variothermal system based on the fluid-fluid process. It alternately connects the hot and the cold device with the same temperature control circuit. With a suitable arrangement of the temperature control channels, existing tools can also be used. The Vario-5 is characterized by simple and quiet operation. It supports the user in determining the optimum setting.

Together with two temperature control units, the Vario-5 forms a variothermal system according to the fluid-fluid technique. Alternatingly, it links either the hot or the cold unit to the same circuit. It is quite possible to use existing moulds if the temperature control channels are suitably arranged. Vario-5 provides easy and quiet operation. It supports the user in determining the optimum settings.

Applications of variothermal control

- Elimination of weld lines

- Contour accuracy in the moulding of the finest structures

- Optimal surface quality

- Reduction of high injection pressures

- Reduction of sink marks

Improved temperature control

- Short heating up and cooling down times

- Optimize cycle time and quality

Smaller heating and cooling power requirement

- Buffer volume for energy-saving operation

Variothermal system with standard temperature control units

- Cost friendly concept

- Use of existing temperature control units

- Multiple use of the units, also for standard applications

- Small, squeezes into almost everywhere

Fully automated process monitoring

Highly accurate process management

- Switching procedures are monitored

Variothermal system with standard temperature control units

- Much experience with proven systems

Simple operation

- Clever wizards determine setpoint temperatures, delays and switching times

- Freely selectable control mode

Convenient functions

- Recording of data via USB and analysis in Excel

Silent

- No pressure shocks

- Without compressed air

Durable construction

- Solely non-corroding materials in the hydraulic circuit

- Switching without pressure shocks

Improved protection for the mould

- Closed system without oxygen contact

- Avoids steam, scaling and corrosion

Stay cool after the heat!

- improved part quality

- better tempering

Minimum investment through standard temperature control units

- flexible use of the devices also for normal applications

- Use of existing temperature control devices

- cost-effective plant procurement

- extensive experience with proven systems

Small, clean and quiet

- finds space everywhere

- can also be used in the clean room

- noiseless

Precise, strong and efficient

- high-precision process control

- less need for heating and cooling capacity

Safe, reliable and low-maintenance

- fully automatic process monitoring

- durable construction

- better protection for the tool

Simple, intelligent and convenient

- Central operation via just one Thermo-5 device or a Panel-5 remote control

- Sophisticated assistants determine target temperatures, reaction and switching times

- freely selectable control

- Recording of the data via USB and evaluation in Excel