- Home

- Companies

- T&D WATER & ENERGY GREEN SOLUTIONS

- Products

- T&D - Model SBR - Sequencing Batch ...

T&D - Model SBR -Sequencing Batch Reactor System

T&D SBR plants are totally automatic and equipped with high quality materials and state-of-the-art technologies. These smart systems guarantee the production of an excellent quality water, suitable for re-use in sanitary facilities, gardening or agriculture.

The visual impact of plants produced by T&D Water is always reduced to a minimum, in respect of the natural environment surrounding the installation.

Special attention is paid to the elimination of noise, thanks to the use of silencers and state-of-the-art equipment, which at the same time ensure high output and optimal reliability.

In-depth know-how in the design of SBR reactors is a necessary condition to exploit this type of process to the full, which alone is highly versatile and also, thanks to the automation, very easy to control.

T&D provides its clients with the assistance of highly specialised technical staff, offering on-site experience in this field and the ability to adapt the Sequencing Batch Reactor to different circumstances.

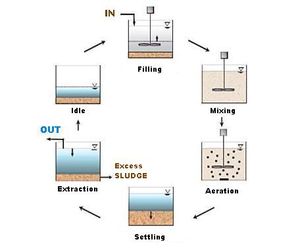

Operation of the SBR plants is using activated sludge with suspended biomass, with total oxidation in discontinuous cycles. Among the main advantages of the SBR process is the optimal flexibility of the system and no sludge recirculation. The various phases and relative duration can be modified according to specific requirements. Combining this with the possibility of managing the process with two or more reactors that can operate alternately, the system guarantees constant output values also in the event of variable loads. The release of unpleasant odours, due to peaks in load concentration is thus prevented.

- Filling: the slurry is gradually immersed until it reaches an adequate height in the tank so that a high quantity of organic substrate is accumulated.

- Mixing: the mixers are activated and the denitrification process starts, under the effect of optional bacteria which need anoxic conditions to develop.

- Aeration-mixing: activation of the aeration system supplies the oxygen required for the aerobic biological reactions with the removal of BOD and the transformation of ammonia nitrogen into nitrates.

- Settling: shutdown of aeration devices and mixing system. This process is performed in absolute silence, exploiting the entire surface of the SBR tank as a sedimentation tank.

- Extraction and idle phase (when relevant): in this phase the purified effluent is gradually collected and clarified after sedimentation; the idol period, if envisaged, coincides with the transfer of the surplus activated sludge to the thickener.