Firmetal Co., Ltd.

Firmetal - Tantalum Wire

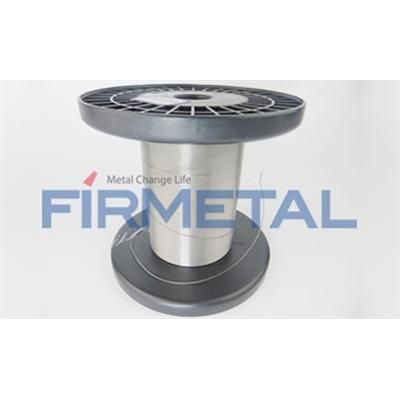

Tantalum powder as raw material is processed into tantalum wire through rolling, drawing and other plastic processing working. The majority of tantalum wire is used in tantalum electrolysis and anode connection in the field of electronic industries.

Most popular related searches

plastic processing

powder metallurgy

emissions source

electrolysis anode

ASTM standard

electrolysis

source emissions

powder processing

Tantalum Wire Products Standard

Firmetal is also the sole supplier of powder metallurgical grade Tantalum 7.5% Tungsten (Ta7.5W), Tantalum 10% Tungsten (Ta10W) and Tantalum 40% Niobium (Ta40Nb) wire. Our products follow ASTM 365 standard.

Tantalum Wire Production Technology

- Tantalum powder as raw material is processed into tantalum wire through rolling, drawing and other plastic processing working. The majority of tantalum wire is used in tantalum electrolysis and anode connection in the field of electronic industries.

- Powder Metallurgy Method:Process: raw material (tantalum powder) → mixing → forming → fusion → rotary swaging → intermediate annealing → drawing → final annealing → inspection → packing

- Smelting Method:Process: raw material (tantalum powder) → mixing → forming → pre-sintering → electron-beam smelting → precision forging → intermediate annealing → rotary swaging → intermediate annealing → drawing → final annealing → inspection → packing

- Pure tantalum wire, 90%Tantalum 10%Tungsten, 97.5%Tantalum 2.5%Tungsten, 60%Tantalum 40%Niobium wire are all made by above technology. They are the most common tantalum alloy products.

Tantalum can be made into wire which is a tenth of a thinner than a hair, this kind of tantalum wire can be used as a suture line for internal surgery, or embedded in artificial eyeballs.The tantalum wire can even replace tendons and nerve fibers.Tantalum wire is the key material for tantalum capacitors, it is used as capacitor anode lead. and tantalum capacitors are the most excellent capacitors. The high-antioxidant tantalum wire can also be used to make tantalum foil capacitors.It can work in potassium dichromate and sulfuric acid, under 100 degrees centigrade and high flash voltage (350V) condition. In addition, tantalum wire can also be used as vacuum cathode emission source, ion sputtering and spraying materials. These products are ideal for use as springs in highly corrosive environments, and as an oxygen getter in lighting applications.