- Home

- Companies

- Nanjing Tengda Machinery Equipment Co., ...

- Products

- TD - Mill Scale Briquetting Machine

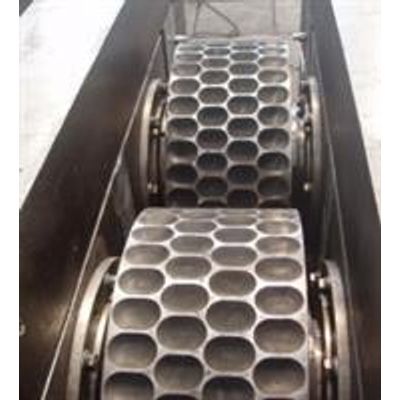

TD - Mill Scale Briquetting Machine

During various stages of iron and steel production a number of iron bearing by-products are generated. Since these by-products can’t be recycled back in fine form, they need to be agglomerated. The traditional way to recycle them back to blast furnace has been the balling and sintering process. Steel mill produce wastes & by-products in large amount every year, such as iron ore fines, coke fines, steel slag, mill scale, filter dust, steel sludge, sinter fines. This is a challenge, and also a great chance. To transform iron-containing residue material into valuable products, briquetting process is an advanced solution.

Due to richness in iron (around 70%), mill scale, an attractive waste, could be directly recycled to the blast furnace. And mill scale briquetting line is necessary to produce briquettes of high strength, density.

Mill scale (namely oxide scale, iron scale, oxide skin), in the form of FeO, Fe2O3, Fe3O4, is generated by oxidation reaction under high temperature.

Mill scale briquetting machine is now popular in Turkey, Oman, India, South Africa, which are rich in iron ore resource.

The application of briquetting technology:

- Ore: iron ore fines, chrome ore fines, chromite ore fines, laterite ore fines, manganese ore fines, nickel ore fines, magnesite

- Fuel: charcoal powder, coal fines, carbon black, petroleum coke, coke

- Mineral: quick lime, burnt lime, gypsum, fluorite, fluorspar, iron concentrate, clay

- By-products in metallurgy: refractory materials, silicon carbide, aluminum dross, residues

- By-products in steel making: sponge iron, mill scale, iron dust, flue dust, steel sludge, fly ash, sintering fines