- Home

- Companies

- TEMA Process B.V.

- Products

- TEMA - Liquid Desiccant Air ...

TEMA - Liquid Desiccant Air Dehumidifier

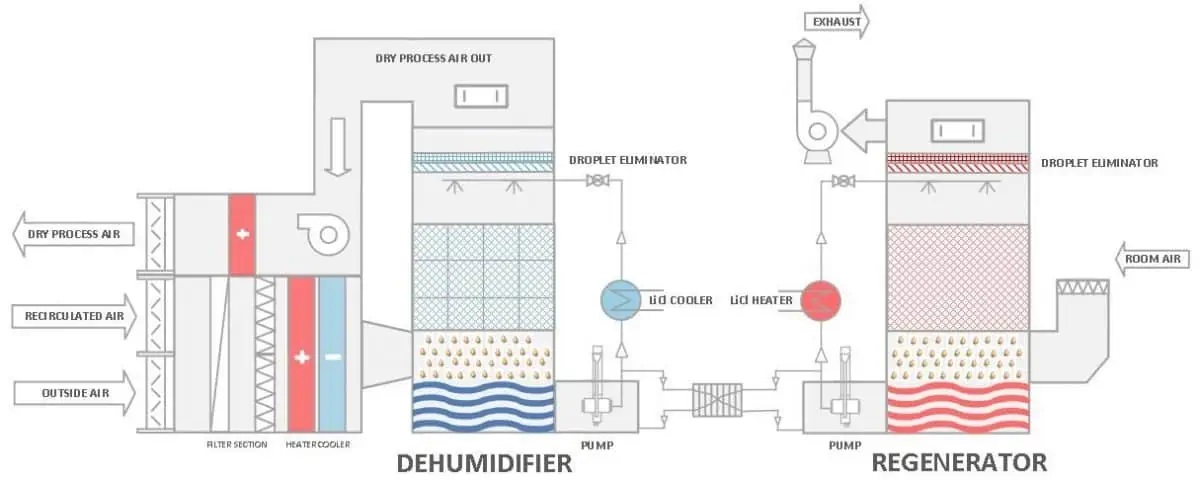

The Tema Process dehumidifier is using a Lithium Chloride salt solution as absorbent. Lithium Chloride is a very strong salt and has an equilibrium curve which closely follows the relative humidity curve of air. The process air will enter the countercurrent dehumidifier and will be dehumidified or humidified in order to maintain this equilibrium. In other words the sprayed salt concentration will control the outlet air relative humidity. By cooling the salt solution before spraying we are able to cool down the air temperature. In this way air temperature and air humidity are both controlled in the same system but can be adjusted independently.

As moisture is continuously absorbed by the salt solution inside the dehumidifier, it becomes diluted and slowly loses drying capacity. To evaporate this surplus of moisture the absorbent is pumped to the regenerator unit. Here the process is turned around, so by heating up the salt solution, moisture is released to an outside air stream and exhausted. The salt solution is continuously pumped between the units in order to provide precise conditions to the process.

Lithium Chloride is a chemically stable, non toxic, non-vaporizing salt solution which acts as a biocide to mold, bacteria and micro-organisms. Beyond its physical desiccant nature Lithium Chloride is also an effective antifreeze.

- The left side of the diagram represents the dehumidifier. It shows the flow of air through various stages.

- Outside Air: The process begins with outside air being pulled into the system.

- Filter Section: The air passes through filters to remove particulates.

- Heat/Cooler: The air is then heated or cooled to the desired temperature.

- Dry Process Air In: The conditioned air then flows into the dehumidifier where it is dehumidified.

- Droplet Eliminator: Before the air exits, it passes through a droplet eliminator to remove water droplets from the air stream.

- Dry Process Air Out: The dry, processed air is then directed out of the dehumidifier for use in the facility.

- The right side of the diagram represents the regenerator which is responsible for regenerating the desiccant material that absorbs moisture from the air.

- Room Air: Air from the room is drawn into the regenerator.

- Liquid Heater and Cooler (Liq Heater/Liq Cooler): The regenerator uses a liquid heater to warm the air and a liquid cooler as part of its operation.

- Exhaust: Moisture-laden air is exhausted out of the system.

- Droplet Eliminator: Similar to the dehumidifier, it also has a droplet eliminator to ensure moisture is removed from the air before it leaves the system.

- The right side of the diagram represents the regenerator which is responsible for regenerating the desiccant material that absorbs moisture from the air.

- Room Air: Air from the room is drawn into the regenerator.

- Liquid Heater and Cooler (Liq Heater/Liq Cooler): The regenerator uses a liquid heater to warm the air and a liquid cooler as part of its operation.

- Exhaust: Moisture-laden air is exhausted out of the system.

- Droplet Eliminator: Similar to the dehumidifier, it also has a droplet eliminator to ensure moisture is removed from the air before it leaves the system.

- Dehumidification and air cooling in 1 step

- Energy friendly: 50-60% more friendly compared to conventional system

- Usage of low temperature heat sources for regeneration

- Usage of low cost coolant sources, f.e. cooling tower water or river water

- Implementation of heat pump

- Microbiological decontamination

- Performance reliability, systems run 24/7

- Precise humidity control (± 1% RH)

- Frost free cooling

- Design flexibility

- Dehumidification and humidification possible

- Dehumidification and air cooling in 1 step

- Energy friendly: 50-60% more friendly compared to conventional system

- Usage of low temperature heat sources for regeneration

- Usage of low cost coolant sources, f.e. cooling tower water or river water

- Implementation of heat pump

- Microbiological decontamination

- Performance reliability, systems run 24/7

- Precise humidity control (± 1% RH)

- Frost free cooling

- Design flexibility

- Dehumidification and humidification possible