Eupry

Temperature Mapping Exercises in Temperature Controlled Environments

FromEupry

Learn the basics about temperature mapping. Get a great idea of how you can perform a professional temperature mapping of your equipment.

Most popular related searches

digital temperature controller

temperature data logger

temperature monitor equipment

temperature monitoring system

data logger

controlled environment

temperature monitoring

temperature logger

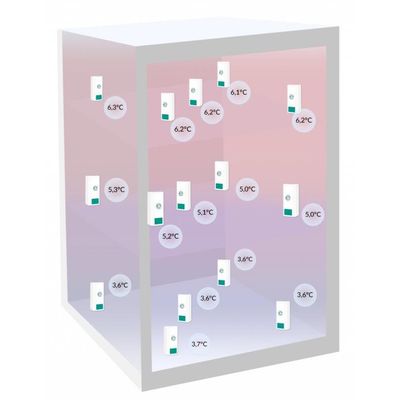

- Temperature mapping of refrigeration equipment is the process that is carried out to prove that the equipment meets the criteria set by authorities and auditors for the equipment and to locate hot and cold zones.

- In other words, a temperature mapping/thermal mapping study documents that the equipment maintains temperatures within defined limits at all times.

- This is especially important to test and document before new equipment is used for storing temperature-sensitive goods in GxP-regulated industries.

- If you are looking for information on how to perform a temperature mapping on specific temperature-controlled equipment and areas, go to this section.

- Inside a fridge, the temperature can vary by several degrees. The temperature in your kitchen fridge can fluctuate by as much as 5 degrees from the top to the bottom.

- The same applies to industrial fridges and freezers, which is the main reason for performing a mapping study before using new equipment.

- Using various temperature data loggers to make the temperature mapping, you will have a clear understanding of how the equipment meets temperature requirements, and which zones can be used for storage and which cannot.

- Last but not least, it will provide you with information on where exactly to place your temperature monitoring equipment.

- Knowing where to place your data loggers, allows you to get a precise measurement of the temperature of the critical goods which will ensure that you receive an alarm the exact minute any temperature deviates from the required temperature range.