- Home

- Companies

- Stable Micro Systems Ltd

- Products

- Stable Micro Systems - Model TA.XTplusC ...

Stable Micro Systems - Model TA.XTplusC -Texture Analyser

Our most popular single column Texture Analyser for universal application.The TA.XTplusC is Stable Micro Systems` flagship texture analysis instrument. A single-column, portable solution for your texture analysis and materials property testing, measuring up to 50kg in force. With a speed range of 0.01 to 40mm/second this extremely precise model can be programmed to conduct almost any mechanical test imaginable, allowing the imitation of real-life situations, using any of our vast range of probes and fixtures. It is also available in both standard and extended heights offering testing apertures of 370 and 590mm, and is consequently the most popular choice for universal texture analysis.

Measure virtually anything

It is capable of measuring virtually any physical product characteristic such as hardness, fracturability, adhesiveness, gel strength, extensibility of foods, cosmetics, pharmaceuticals, gels, adhesives and other consumer products.

The TA.XTplusC is commonly employed to measure and quantify fundamental, empirical and imitative tests in both compression and tension, covering those relating to texture analysis, materials properties as well as effects of rheology of solid, semi-solid, viscous liquid, powder and granulate materials.

Built to last

Coupled with easy-to-use Exponent Connect software, this versatile instrument is extraordinarily well-engineered for long-term reliability and accuracy.

Run from any device

All Stable Micro Systems Connect series Texture Analysers are capable of operation by the standard equipment Touchscreen Interface as well as by a desktop or laptop PC. In addition, they may also be operated from a mobile phone or tablet using the Browser Interface. Learn more

- Measure and quantify your product’s textural/mechanical properties objectively and accurately which can be archived and retrieved for future viewing.

- Determine the textural/mechanical properties of your ‘gold standard’ product to ensure consistent quality control of your products into the future.

- Assess raw materials, ingredients, excipients, semi-finished goods, packaging and finished components or products.

- Determine the effects of formulation or processing variables on end-product acceptability

- Assess textural/mechanical property changes during storage or transportation

- Compare your products with competitive products

- Substantiate your product claims

- Force Capacity: 50kg.f (500N)

- Force Resolution: 0.1g

- Loadcells: 0.5, 5, 30, 50kg.f

- Speed Range: 0.01 – 40mm/s

- Maximum Aperture: 370mm/590mm

- Distance Resolution: 0.001mm

- Data Acquisition Rate: 2000pps

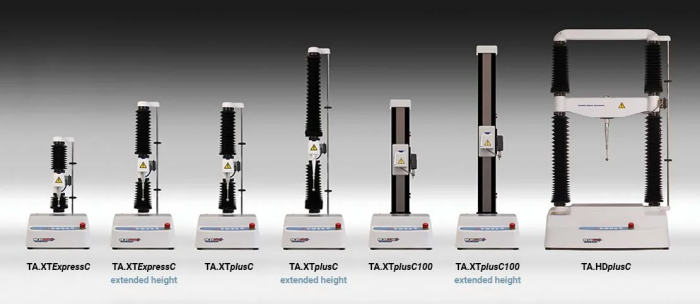

Not sure what specification or model you need? Compare Texture Analysers

- Globally recognised instrument

- World class data analysis software

- Widest range of probes, fixtures and accessories

- Complimentary software updates for the life of your instrument

- Complimentary technical support

- Unrivalled inbuilt test advice library

- Extended warranty

- Bespoke test solution service

- Over 30 years expertise

The instrument of choice for leading companies and universities across the globe

While our consumers are aware that our instrument is the best in the world, their decision to purchase one is not just based on the hardware. Ultimately, it all comes down to the service we provide to all of our customers. When considering the purchase of a Texture Analyser, our clients consistently cite our experience and desire to assist them with testing issues of all shapes and sizes as the number one reason why a Stable Micro Systems instrument is, and will always be, their first option. There`s a reason why why we are the most academically referenced Texture Analyser in the world according to Google Scholar – we offer the complete cutting edge solution

Further information Texture Analyser buying advice

Read our guide Seven Tough Questions you should ask before buying a Texture Analyser

Case Studies

Explore our case studies to see how our customers have used their instruments to further their testing requirements and find solutions to testing problems.

Discover the wide range of texture and physical properties that can be measured with a texture analyser.

Texture Analysers are used to measure many properties, such as Hardness, Brittleness, Spreadability, Adhesiveness, Tensile Strength, Extensibility etc., on a vast range of products.

Our range of instruments can carry out fundamental, empirical and imitative tests, covering those relating to texture analysis, materials science and rheology of solid, semi-solid, viscous liquid, powder and granulate materials.

Food Texture Properties

Foods are a selection of semi-solid, soft-solid, viscoelastic materials, and occasionally hard solids. Oral processing of these foods starts with either biting a portion from a larger piece or placing a piece in the mouth. Food texture is one of the key properties consumers evaluate when determining food quality and acceptability and embraces a large number of textural characteristics or properties.

Specific textural elements of a food are evaluated by descriptive sensory analysis; however, the time and costs of sensory analysis have motivated the empirical development of mechanical tests that correlate with sensory analysis of texture. Now parameters can be objectively obtained that present measures of, for example, crispness of a potato chip, spreadability of margarine or the firmness of an old fashioned, New York style bagel.

Physical Properties of Materials

While food scientists were evaluating mechanical properties to understand subjective texture, material scientists were developing rheological and fracture-mechanics approaches to understand material properties in general. Materials have physical or textural/mechanical properties that are also perceived and are measurable. From an engineering perspective, an engineer would need to know and usually measure the mechanical properties of a material in order to make an informed decision when designing something.

The main physical concept behind measuring mechanical properties is stress. Stress tells you how big a force applies to an area. The second important concept is strain which is a ratio of lengths. From these two concepts, the Young’s Modulus can be derived, which is a measure of stiffness/elasticity – important factors for engineers when deciding material suitability for a certain application. In addition, such parameters as adhesion, abrasion, friction, flexure, strength etc. can be measured.

Specialist attachments enable the instrument to emulate forces applied to products in everyday consumption or usage. The data captured by Exponent software during the test procedure is used to generate graphs which detail the reaction of each test sample to specified forces.

Below is shown a range of textural properties that Stable Micro Systems tends to encounter most often...

- Abrasion

- Actuation Force

- Burst Strength/

- Resistance

- Chewiness/ Bite Force

- Cohesiveness

- Combability

- Compressibility/ Compactability

- Consistency

- Crispness Crunchiness

- Disintegration

- Extensibility/ Elongation

- Extrudability

- Firmness/ Softness

- Flexibility/ Bending Force

- Flowability/ Caking

- Fracturability/ Brittleness

- Friction

- Gel Strength

- Hardness

- Mucoadhesion/ Bioadhesion

- Peel Strength/ Seal Strength

- Ripeness

- Rupture Force

- Spreadability

- Springiness/ Recovery

- Stickiness/ Adhesiveness

- Stringiness/Shortness/ Tailing

- Swelling/ Proving

- Syringeability

- Tensile Strength/ Break Strength

- Toughness/ Cutting Force

- Viscoelasticity

Click on your area of interest for information on a relevant range of attachments, and to view videos and more detailed background on our blog.

Every industry has products which have a consumer/end-user expectation of the physical/mechanical properties whether it is industrial materials, cosmetics, food, adhesives or pharmaceuticals.

Because of its adaptability, texture analysis has become commonplace in many industries to measure a specific or range of characteristics or properties relating to the way a material behaves, breaks, flows, sticks, bends, etc.

Whether it’s in new product development or as part of quality control procedures, major manufacturers routinely apply texture analysis techniques to carry out a wide range of measurements. Tests could be performed to analyse raw materials or excipients, semi-finished goods, packaging and finished products – the application of texture analysis could be at any stage of manufacture.

A Texture Analyser can be employed to determine the effects of raw material or excipient quality as a result of substitution or the adjustment of formulation or processing variables on end product acceptability. This could be to measure the ‘mouthfeel’ properties of food, the flow properties of creams and pastes, the compressibility/tensile strength of packaging, the break or bend of a product or the tackiness of adhesives.

Within each industry there are textural/mechanical properties that are particular to its products. Each product has properties that are either expected or undesirable and it is the job of a Texture Analyser to objectively measure these characteristics to ensure your products meet their physical requirements and consumer expectations.

Discover the typical texture analysis solutions that have been developed for products in each industry below:

Food Materials and Products General

Texture Analysis

Now you`ve taken a first look at Texture Analysis, why not ask for some more information...

Discover more about scientific texture analysis

Our experienced sales representatives will give you all the advice and information you need

... you should ask before you buy a Texture Analyser

Find out about the Stable Micro Systems Texture Analyser family

Food

- Cereals

- Confectionery

- Dairy

- Fruit and Vegetables

- Meat and Fish

- Pasta and Rice

- Snacks

- Petfood and Animal Feed

Materials and Products

- Adhesives

- Controlled Release Products

- Cosmetics and Skincare

- Dental

- Electronics

- Hair and Hair Products

- Leather

- Materials

- Medical Devices

- Packaging

- Personal Care Products

- Pharmaceutical and Medical

- Polymers

General

Measure more than force – sound, video, temperature – just a few of the non-textural properties that can be measured simultaneously.

Whilst a TA.XTplus/TA.HDplus Texture Analyser is commonly used for the collection of force, distance and time data, it also has the capability of capturing additional measurements.

For products that are temperature sensitive, a range of temperature control options can connect to the Texture Analyser and enable control, capture and monitoring of temperature. Additionally, for brittle samples (or products that emit ‘noise’ during testing) an Acoustic Envelope Detector provides the means to collect sound data which can offer ‘a fourth dimension in texture analysis’.

By fitting a Powder Flow Analyser onto your Texture Analyser, you have the ability to measure powder flow. Meanwhile, the installation of a Dough Inflation System will convert your Texture Analyser to enable measurement of pressure and volume whilst inflating dough. All data can be viewed graphically and, in the case of sound, weight, humidity and temperature, can be plotted on a second Y axis (effectively overlaying your texture data) to be able to see any correlations that may be present.

In the case of Video Capture & Synchronisation – why miss a texture analysis moment, when you can record and replay your tests later (frame by frame) to obtain a clear understanding of your sample`s behaviour.

Whatever your testing requirements – from sausages to stents, personal care products to powder – we have an instrument to suit.

Which Texture Analyser should I choose?

Your choice of instrument is likely to depend upon your maximum force requirement, your maximum operating distance requirement, the simplicity of your testing needs or your desire to operate with the most sophisticated data analysis and presentation features and expandability of additional data collection, either now or in the future.

If you are unsure of what specification of instrument you need, let us help you understand the benefits of each model or whether your require a PlusCseries or ExpressCseries of instrument. We can help you conduct a cost-benefit analysis for each instrument option to achieve your current and future testing needs. Request advice from an expert

The TA.XTExpressCTexture Analyser

An entry level and QC-based texture analysis option when compared to our sophisticated full-featuredPlusrange. It offers cost-effective portable analysis for a wide range of low force applications. With a choice of two dedicated software packages or keypad operation, the instrument is easily configured to meet the user`s exact requirements. Test profiles are stored for immediate use and the results analysed automatically using either `in-built` Standards, such as TPA or Bloom, or product specific procedures.

TA.XTplusCTexture Analyser

A small portable solution for texture analysis and mechanical property measurement of your materials, measuring up to 50kg in force, and is consequently the most popular choice for universal texture analysis.

The TA.XTplus100CTexture Analyser

This instrument retains the benefits of the TA.XTplusC, with the additional capability of utilising forces up to 100kg, along with an improved distance resolution, doubled to 0.0005mm. This instrument is therefore more favourable to the testing of harder products or those with greater tensile strength and elongation measurement needs – the highest force and distance choice in a single column instrument.

TA.HDplusCTexture Analyser

Offers a maximum force capacity of 750kg (7.5kN), and a family of intelligent, factory calibrated loadcells down to 0.5kg. It can perform precision testing to a few grams without compromising accuracy, whilst providing the required rigidity to accommodate measurements of considerably higher force for heavy-duty and materials testing applications. The greater testing bed area and height range offer the ability to test much larger samples within a twin column frame, making this instrument the obvious choice for users testing a wide range of products, or for those who have an uncertain future product testing requirement.

Why is a plus model of instrument the best choice?

Whether you choose a TA.XTplusC, a TA.XTplus100Cor a TA.HDplusC, aPlusmodel of instrument offers the most versatile and innovative materials characterisation solution.

Distance resolution

Micron level distance resolution allows this extraordinarily well-engineered instrument to provide precise deformation of materials and extremely thin/small samples.

High speed data collection

OnlyPlus instruments can collect data at 2000 points per second. This will provide enhanced detail to your sample testing which could be crucial to those tests that involve fracture or quick events that could otherwise be missed with less data.

Exponent Connectsoftware

Unparalleled in its data analysis and presentation formats,Exponent Connect software is the choice for operators looking to take advantage of all of the options available in the design of their testing solution. Multi-stage programming allows users to define individual arm sequences at various speeds, forces and distances, conduct sinusoidal or constant strain rate tests, in either compression or tension.

Additional Measurement Options

If you wish to measure and plot temperature, humidity, sound, weight, resistance and synchronise video captured frames with your data you’ll need aPlus instrument. Additionally, aPowder Flow AnalyserorDough Inflation System are examples of devices that can be attached and controlled offering expansion of your measurement options.

Automation Options

ThePlus range allows automation of your testing protocols and analysis to provide efficiency to your product testing. The attachment of anAutomated Linear Indexing System is one such example, only able to attach toPlus instruments.

Future proof innovation

All of the best features and ideas are built into thePlus range of instruments. Whether you need the features now or in the future, we will continue to enhance the performance of the instrument and improve the data analysis options of its software beyond the scope of competitive instruments. ThePlus range is a choice of long-term investment that keeps pace with your evolving testing needs.