- Home

- Companies

- Birk Wärmetechnische Anlagen GmbH

- Products

- Birk - Thermal Afterburning Plants for ...

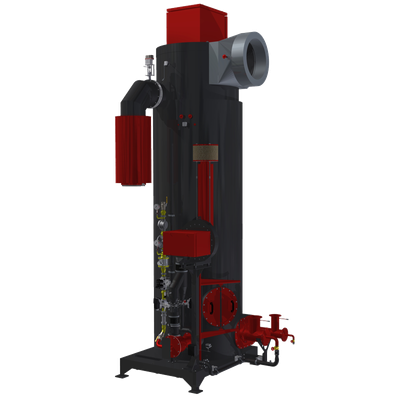

Birk - Thermal Afterburning Plants for Exhaust Air Purification

Birk Wärmetechnische Anlagen GmbH is a specialized company in the field of exhaust air purification and post-combustion systems. The company designs and develops highly efficient plants customized to meet specific client requirements. Their expertise covers multiple types of thermal afterburning technologies including Thermal Afterburning (TNV), Regenerative Thermal Post-Combustion (RNV), and Catalytic Afterburning (KNV). These technologies are employed to remove harmful components from exhaust air or gases through oxidation processes, ensuring compliance with environmental and statutory regulations. The TNV systems operate at working temperatures ranging from 650 to 1200 °C to convert contaminants into harmless substances like water and carbon dioxide. RNV systems integrate heat recovery for process exhaust air preheating, achieving temperatures of 650 to 900 °C, making them suitable for large exhaust air volumes without additional heat generation. KNV systems use catalysts to lower reaction temperatures (250 to 400 °C), making them ideal for industries like surface treatment, furniture production, and food processing. Each system is designed for highly flexible adaptation to various processes and spatial constraints, optimizing both economic and environmental performance.Exhaust air purification is the removal of harmful constituents and components before they are discharged into the environment or atmosphere.

An exhaust air cleaning or exhaust gas cleaning system is required in order to comply with official and statutory regulations regarding the introduction of process exhaust air into the environment. In air pollution control, the terms exhaust air cleaning, exhaust gas cleaning or afterburning are often used under the same background.

Schedule line characteristics can be considered:

- The term "exhaust air" is often associated with "production" exhaust air, for example - this is usually relatively cool, usually below 100°C media temperature.

- In return, the term exhaust gas is used for warm exhaust air. The media temperature here is usually above 100°C and usually comes from heat treatment plants. Both terms have a relatively high air content in the medium.

- The term afterburning, on the other hand, is frequently used directly in the thermal treatment of raw gas or system gases, among other things, from the fields: Debinding, coking, decoating, pyrolysis, carbonisation. Common to all these processes is the generally air- or oxygen-free process gas formation, which is subsequently fed to the post-combustion plant. To simplify matters, the general term "exhaust gas" is also used for this type of process gas.

Thermal afterburning is an exhaust air cleaning or exhaust gas cleaning system using oxidation.

Depending on the process or clean gas requirements, working temperatures of 650...1200 °C with corresponding residence times of at least 0.7 sec. are realized in the TNV combustion chamber. Thermal post-combustion is an air-hygienically optimal process, since the exhaust air or exhaust gases, with the exception of sulphur, halogens or other thermally non-decomposable foreign substances, are completely converted into the harmless substances water (H2O) or carbon dioxide (CO2).

Areas of application and advantages:

- suitable for one VOC load >1 gC/Nm³

- VOC Separation efficiency >99.8%

- very wide range of applications

- fast starting and stopping possible

- autothermal operation with concentration above 6-8 gC/Nm³ possible

- particularly suitable for strongly fluctuating process conditions (exhaust air volume flow, pollutant concentration, temperatures, ...)

- only process for the incineration/disposal of liquid pollutants

The "thermal afterburning" process is absolutely flexible with regard to the type and composition of the exhaust air or raw gases to be introduced and can therefore be adapted to all conceivable processes.

Any oxygen content bound in the raw gases or the exhaust air does not play a role in the combustion or oxidation process starting in the post-combustion chamber. When raw gases are introduced from an inert process, the required oxygen is fed separately into the reaction chamber. When exhaust gases from an air-guided process are fed in, the required oxygen content is already contained. The exhaust gas and fuel gas are combined by means of a special combustion plant of our greenfire generation.

Thermal afterburning plants from Birk Wärmetechnische Anlagen GmbH are specially adapted to each customer process and can also be subsequently adapted or extended to other processes. They offer the possibility of the simultaneous introduction of exhaust air, as well as exhaust gases (raw gases) and liquids (condensates, etc.) - the "Birk" TNV plants are therefore often called "omnivores" by our customers.

Our TNV systems are specially designed and adapted to the customer's installation site, so that a cost-effective and effective exhaust air/flue gas cleaning can be realised even in confined and minimal space conditions.

- Compact design

- System versions for vertical, horizontal or suspended installation

- System designs for indoor or outdoor installation

- Option: Version for installation in EX zones of various categories

- Option: Version for installation in the food sector

- System installation (standing, lying, hanging,...as well as indoors or outdoors) Any

- System designs for volume flows: 10 mn³/h to 50,000 mn³/h

- Plant designs for raw gas/polluted gas mass flow: 0.5 kg/h to 1000 kg/h

- Equipment designs for mixed operation - so-called "omnivores

- over 90% energy and heat recovery possible through system combinations

- integrated and external process air preheating at the TNV combustion chamber

- Possible combinations of heat recovery for the processes:

Process air/air heaters

Warm/hot water production

steam generation

Thermal oil production and others - Firing and heating technology for gases, oils, liquids and others - as well as by means of electric heating registers

- Own efficient burner technology for the combustion plant in low NOx technology

- SNCR and SCR concepts for nitrogen oxide reduction

- Integration of a RAD adsorber for concentration and minimization of the pollutant gas flow

- Combination and delivery with desulphurisation, dedusting and other measures for the removal of non-oxidisable foreign substances possible

- Advanced technology for minimal maintenance

- Portfolio of cost-effective "standard" TNV systems in specified sizes and applications

Regenerative (thermal) afterburning is an exhaust air purification system using oxidation and integrated heat recovery for process exhaust air preheating.

Depending on the process or clean gas requirements, working temperatures of 650...900 °C are achieved in the RNV combustion chamber with corresponding residence times.

Like the TNV process, regenerative afterburning is an air-hygienically optimal process, since the exhaust air is completely converted into the harmless substances water (H2O) or carbon dioxide (CO2). Regenerative post-combustion plants offer a great deal of savings potential through integrated heat and energy recovery for the process air, whereby the energy costs to be used are minimised or, in autothermal processes, reduced to the use of electrical energy.

The "regenerative afterburning" process is particularly recommended for higher exhaust air volume flows and for processes in which no further generation of process heat (warm/hot water, thermal oil, steam) is required. Our regenerative post-combustion plants are specially adapted to each customer process and can also be subsequently adapted or extended to other processes. Our RNV plants are specially designed and adapted to the customer's installation site, whereby a cost-effective and effective exhaust air cleaning can be realised even in confined and minimal space conditions.