- Home

- Companies

- Haemers Technologies SA

- Products

- Smart - Thermal Desorption Soil ...

Smart - Thermal Desorption Soil Remediation - Conductive Heating Burners

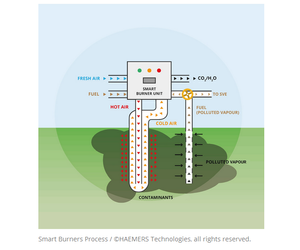

Thermal Conductive Heating using Smart Burners Technology was specifically developed to solve soil pollution problems and may be the perfect answer in urban environments.

The principle is a two phases process:

-

The soil is heated up to a temperature where contaminants vaporise

The soil is heated by stainless steel heating tubes put into the soil, through which hot air is circulating.

-

The polluted gases are extracted and the contaminants are recycled

Vapors containing the volatilized contaminants are recovered through a separate soil, vapor extraction network and recycled either as fuel in the smart burners or as liquids after condensation

Soil can be re-used and no organic contamination is left behind. Each heater is designed for in-situ or ex-situ implementation confined environments (such as basements or existing buildings). It can be applied in large sites as well as in Smart burners can be applied alone or in combinations with other technologies for optimal result.

-

Very flexible system, easy to transport, install and demobilize

The Smart Burners system consists of small heating units (burners) connected to steel tubes that serve as heating elements. Each burner and tube can be considered to be a thermal unit.

-

Limited nuisances (excavation, noise, odors, traffic, etc.)

No excavation and transport of soil necessary.

-

Affordable and fixed price, fast execution

Especially when needed for a real estate transaction. It is priced as an alternative to other technologies, especially other (thermal) options to eliminate the contamination, that are substantially costlier.

-

Scalable, flexible and easy-to-handle system

“Only heat what you need to treat”

-

Flexible installation heaters, everywhere

Even where difficult access impedes other technologies, Smart Burners Technology allows to be applied in nearly any configuration (horizontal, vertical, slant) including under buildings, in basements and subterranean utilities.

In Situ Thermal Desorption using Smart Burners Technology was specifically developed to solve soil pollution problems. ISTD can solve remediation problems which could not be solved with other technologies. This is the perfect answer in urban areas. Each light weight heater is designed for in-situ works in open, as well as in confined environments (such as basements or existing buildings).

The benefitsof using Smart Burners for ISTD:-

Sustainable and complete remediation in short time

No contaminant left behind

-

Remediation under existing buildings

No demolition of buildings. Soil can be cleaned without excavation, even in difficult approachable spots

-

Even in difficult access areas

Inside buildings and near infrastructure

-

Limited nuisances for the neighbourhood

Excavation, noise, dust, odors, traffic, etc.

-

All organic contaminants and all soil types

With thermal desorption all organic contaminants can be treated

-

Reduction of energy costs and ecological system

Hydrocarbons are volatilized during a thermal desorption process, they are extracted of high temperature and their energetic content could be reused.

Ex Situ Thermal Desorption (ESTD) using Smart Burners Technology is a system that is used for onsite soil treatment, when the soil is treated on site after excavation (no transportation off site).

The principle:-

While building the pile, heating and extraction wells are layered into the soil. On the first layer of contaminated soil, a range of wells is placed. Then again a layer of soil, a range of wells, etc. In a standard design, piles are 20 meters long and between 2.70 and 6.40 meters high.

-

The volume of the soil to be treated determines the final width. In case of large volumes, the number of soil treatment units will be multiplied, and are set up week after week. As a result, with such an overlapping setup, large treatment capacities can be achieved with reasonable costs.

-

Sustainable remediation

Recycling of contaminants and low energy consumption

-

Scalable to fit any size ESTD project

Even small sites in urban areas or very large quantities in many batches

-

No large and costly power upgrades

With natural gas or propane/diesel supplying the energy for heating, large and costly power upgrades are not required

-

Energy and cost savings

The use of individually controlled Smart Burners allow for precise heating what is needed and no more, which translates to energy and cost savings

-

Even on remote sites

A generator can be used for equipment that requires electric power (i.e. blowers, Smart Burner controls, etc.) for a completely off the grid system.

With thermal desorption all organic contaminants can be treated, as all these chemicals will vaporise at a given temperature and can be extracted from the surface for further treatment. Here is a ist of he most common pollutants found in soils and treated by thermal desorption (incl. Smart Burners )

The pure organic contaminants (only hydrogen and carbon) will not only be desorbed, but also be completely oxidized in the combustion chamber. There will be no other release into the atmosphere than CO2 and H2O.

Halogenated Hydrocarbons: PCB, Dioxins, Furans, PesticidesThe principle of desorption remains the same for halogenated hydrocarbons (chlorinated solvents, PCB, dioxins, furans, pesticides, etc.), i.e. that they will evaporate and be collected in the gas phase (their boiling points are all well below 550°C). Once oxidized, the halogens will remain in the gas phase and therefore a secondary gas treatment is required before release into the atmosphere.

Chlorinated solventsThe boiling point of chlorinated solvents is below 100°C, so the target temperature of the soil can even be below. This implies that these chemicals can also be treated in (ground)water.

CyanidesRegarding the treatable inorganics, such as cyanides and mercury, their behaviour is very specific. Cyanides are desorbing easily (depending on the complexes, the boiling temperatures varies from 300°C to 420°C) and are oxidized to CO2 and NOx in the burner’s flame. In order to not exceed the limit values the exhaust gas composition needs to be followed carefully; otherwise a secondary treatment is required.

MercuryAlthough obviously heavy metals cannot be treated thermally, mercury is a particular case. It can be desorbed as nearly all forms of mercury have boiling points well below 550°C. However, the off-gas cannot be oxidized. Therefore mercury impacted materials require special attention and a dedicated unit.

Off gas treatmentCombustion of off-gas

In all cases, hydrocarbons are volatilized during a thermal desorption process (the Smart Burners Technology process) and, as gases, they are conveyed to a combustion chamber where they are oxidized to CO2 and H2O, with a generation of energy.

Other treatmentIn some cases hydrocarbons may contain other elements, like sulphur or chlorine, which are not oxidized to CO2 and H2O and need additional gas treatment in order not to exceed the emission standards set for the release of clean gasses into the atmosphere. Standard methods like condensation and the use of activated carbon are applied here.