Bionetics Rheotherm - Model 210 -Thermal Low Flow Liquid Meters

Low flow liquid meters are specialized flow measurement devices that measure small liquid volumes and low flow rates. These low flow liquid flow meters are essential for monitoring and controlling liquid flow in processes demanding high precision. The Bionetics Corporation provides Rheotherm flow meters, including Rheotherm Model 210 flow meters, which are an excellent—often the only—choice for reliable liquid flow measurement at low flow rates. The Rheotherm Model 210 liquid flow meters operate on the principle of thermal mass flow measurement.

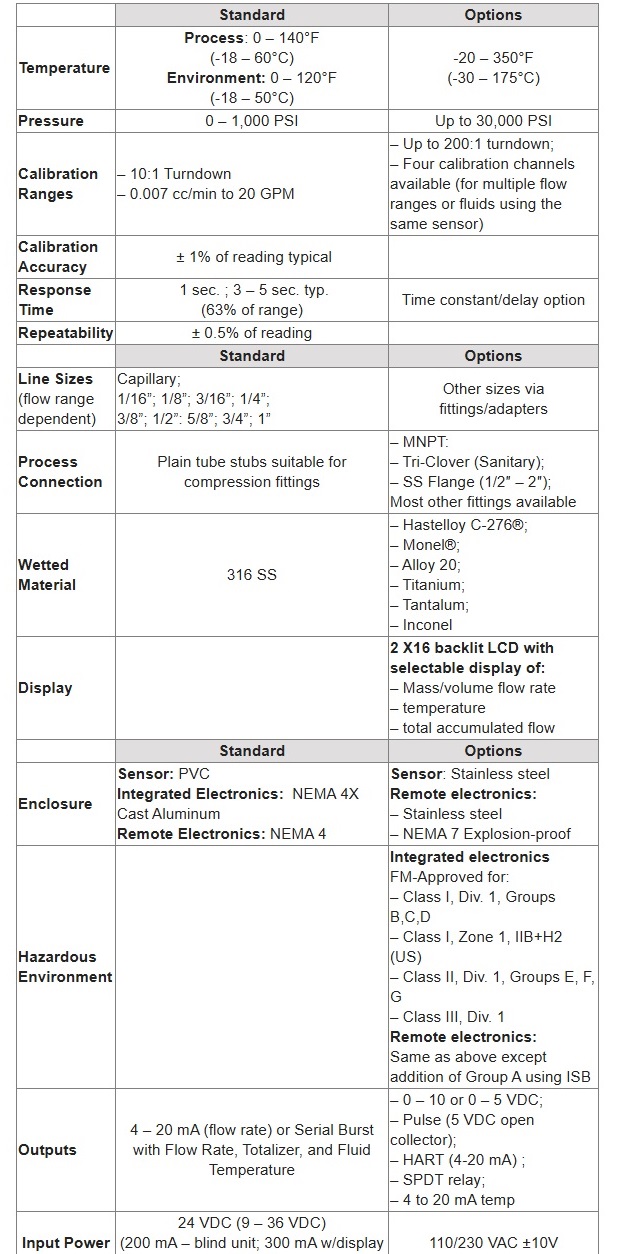

Our low flow liquid flow meters are ideal for flow rates from 1 gallon/year to a few gallons per minute (GPM). These flow meters are maintenance-free, and deliver repeatable and reliable results. We also provide low-volume flow meters for hazardous environments, including intrinsically safe and NEMA 7 explosion-proof models. Being a market leader in flow monitoring devices since 1978, we ensure the highest standards of quality and reliability. All our low flow liquid meters are ISO 9001:2015 certified.

The installation process of Rheotherm high-accuracy liquid flow meters is straightforward as discussed below.

Rheotherm flow meters feature inline flow sensors installed using standard tube fittings. They are optionally offered with flanges, sanitary fittings, and other configurations to meet your application requirements.

The flow meters can be installed in any orientation, except vertical with a downward flow direction.

Some models have integrated electronics, whereas others have a separate electronics enclosure that can be installed up to 200 feet from the sensor. This option is beneficial in restricted spaces.

Choose FM-approved intrinsically safe sensors and/or FM/cFM-approved explosion-proof integral units for hazardous environments. Please visit our page on Electronics Options for various models of Rheotherm low flow liquid meters.

The Rheotherm Model 210 liquid flow meters or inline water flow meters operate on the principle of thermal flow measurement. It determines the flow rate by analyzing the thermal properties of the fluid passing through the device’s body. The meter utilizes a straight-through or looped flow tube, and two resistance temperature detectors (RTDs) mounted on the tube’s exterior. Generally, a heated and unheated RTD is used for the process. The temperature differential between these RTDs provides the primary flow signal. The differential is lower at high flow rates because the heat is removed effectively through the flow. The differential is higher at low flow rates due to reduced heat removal. The continuous and consistent flow of homogenous liquid ensures accurate flow measurement without gauging the fluid pressure.

The unobstructed fluid path ensures that the fluid only contacts the fluid tube wall. Even the presence of solids in the fluid will not damage the sensor. In short, the unobstructed fluid path helps eliminate wear, tear, or breakage of mechanical parts. The Model 210 is available without a local display but has an optional 2 x 16 backlit LCD display that shows mass/volume flow rate, temperature (°C or °F), and total accumulated flow.

Flow data can be extracted in both digital and analog formats, allowing routing to the digital display or an off-site computer. Additionally, the Model 210 has a self-diagnostic feature that automatically detects system issues and generates fault codes for user review.

Eager to learn more about the method of operation of Rheotherm inline digital flow meters? Please visit our Rheotherm Method of Operations page.

Explore the key features of our low volume flow meters that enhance their performance, reliability, and ease of use across applications.

- No moving parts

- Exclusive inline TU sensor

- Typical calibration ranges: 10:1 and options up to 200: 1 turndown

- Durable sensors, unaffected by over-ranging

- Advanced signal processing electronics

- Field adjustable; easy onsite calibration adjustments

- Maintenance-free

- Easy installation

- Choice of wetted materials

- Long-term reliability

- Stores up to four calibration curves

- Extended temperature compensation

- Optional remote electronics configuration

- Hazardous environment options